The wireless proximity technology known as

Near Field Communication, or NFC,

has been making headlines recently, especially in the consumer sector. Look at

just about any news site, and you’re likely to find an announcement

about some kind of NFC-enabled application, whether it’s mobile

payments, wearables, next-generation ticketing schemes or new sharing

services like short-term bike and car rentals. What hasn’t been getting

as much coverage, though, is the promise NFC shows for manufacturing, and the

many ways it can make factories smarter, more efficient and more productive.

Added intelligence

Today’s factories are already pretty smart, using technologies like

cloud computing, the Internet of Things, omnipresent connectivity and

advanced automation to increase output, support customization on a large

scale, respond more quickly to changes in demand and, of course, save energy

and lower costs.

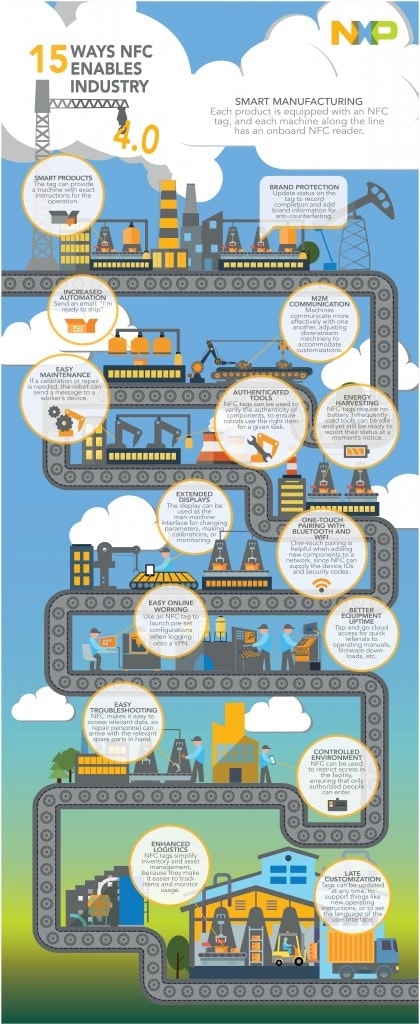

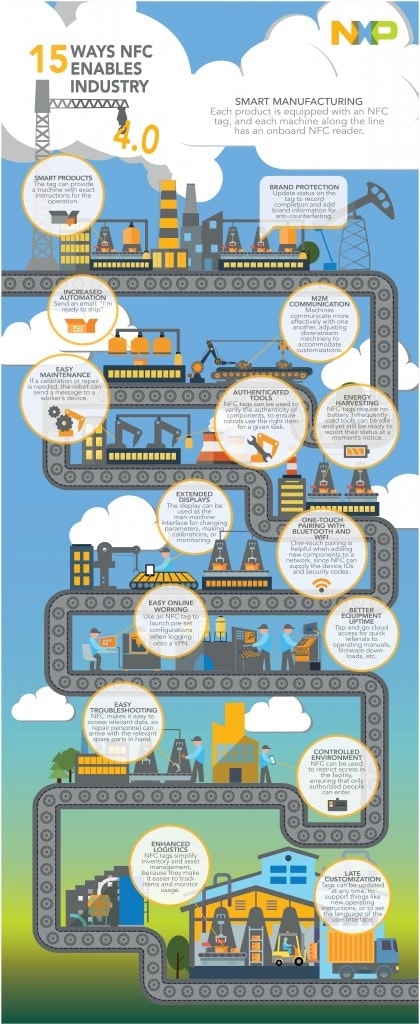

NFC is a welcome addition in these sophisticated production environments,

because it delivers new levels of convenience, communication and

configurability throughout the supply chain, from initial production to

warehousing, the store shelf and beyond. NFC works in many different ways to

enhance manufacturing, and we’ve identified the top 15 advantages.

Learn more

To get the details about our top 15 list, download our new white paper,

titled “What NFC means for smart factories, intelligent supply chains and Industry 4.0”.

Join the conversation

Where do you think NFC fits in the supply chain? And how might you use NFC

tags to make production smarter? Do you own any products that use NFC tags?

Related links

A closer look: NFC-enabled manufacturing

NFC - Near Field Communication