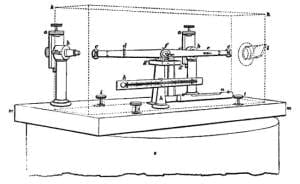

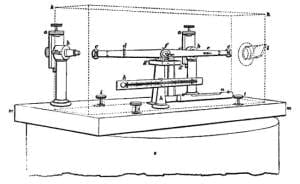

I love browsing old 19th and 20th century engineering

textbooks. It’s great fun seeing the ingenuity that our technical

predecessors used to take measurements that today we consider routine or

mundane. The vertical force magnetometer here is one example.

This figure and theory of operation was published by the

Royal Society of Edinburgh in 1848

and is available to anyone today, courtesy of Google Books.

163 years later, we have technologies for taking magnetic measurements based

on any number of physical phenomena and targeted at almost any range of

measurement needed. With names like AMR, GMR, TMR, Squid, fluxgate,

magneto-inductive, SERF and Caesium vapor, it’s easy to get confused.

If you are working in the consumer area, you can probably rule out most of

these.

163 years later, we have technologies for taking magnetic measurements based

on any number of physical phenomena and targeted at almost any range of

measurement needed. With names like AMR, GMR, TMR, Squid, fluxgate,

magneto-inductive, SERF and Caesium vapor, it’s easy to get confused.

If you are working in the consumer area, you can probably rule out most of

these.

It’s only recently that price points have reached the level where we

can expect to start seeing magnetometers in low-cost consumer devices.

The ones that get my attention are those based on magnetoresistive technology

(AMR, GMR and TMR) and magneto-inductive.

Magneto-inductive sensors, like those offered by

PNI Sensor Corp., have an advantage in that they have no need to reset magnetic domains of

the material. I own a PNI game controller and use it often. One downside is

space, Z-axis devices of this type may not fit in tight environments

like cell phones. Magneto-resistive technologies such as those offered by us

and other vendors share a common technology base with your average CMOS

integrated circuit. X, Y and Z sensors are easily integrated into a single,

physically small, package.

Magneto-inductive sensors, like those offered by

PNI Sensor Corp., have an advantage in that they have no need to reset magnetic domains of

the material. I own a PNI game controller and use it often. One downside is

space, Z-axis devices of this type may not fit in tight environments

like cell phones. Magneto-resistive technologies such as those offered by us

and other vendors share a common technology base with your average CMOS

integrated circuit. X, Y and Z sensors are easily integrated into a single,

physically small, package.

Since sensors for all three axes can be combined into a single die using

standard IC manufacturing processes, cross-axis errors are minimized. The

MAG3110 goes one step further and includes a second die which provides signal

conditioning, analog-to-digital conversion and digital host interface.

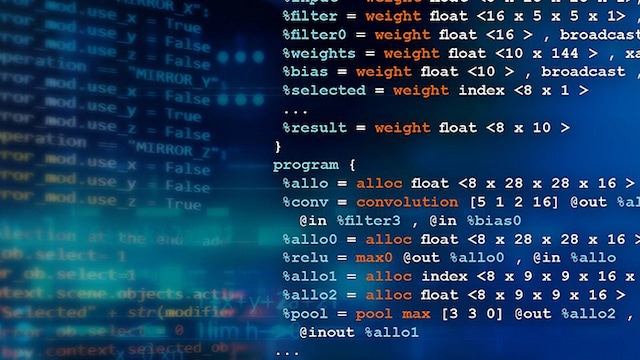

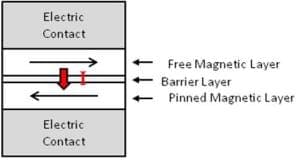

TMR Magnetometer Principles of Operations

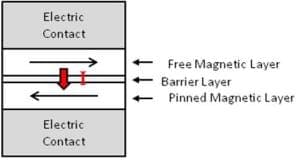

Our magnetometer

utilizes an effect called tunneling magneto-resistance (TMR) which is based

upon the magnetic tunnel junction (MTJ) illustrated below. The device includes

two electric contacts, two magnetic layers and one barrier layer. In the

figure, the tunneling current I is controlled by the relative

orientation of the magnetic fields in the free and pinned magnetic layers. The

current “I” is maximized when the fields in both layers are

aligned with one another. It is minimized when the two fields have opposite

polarity. Essentially, the MTJ acts as a resistor which is dependent upon the

magnetic field.

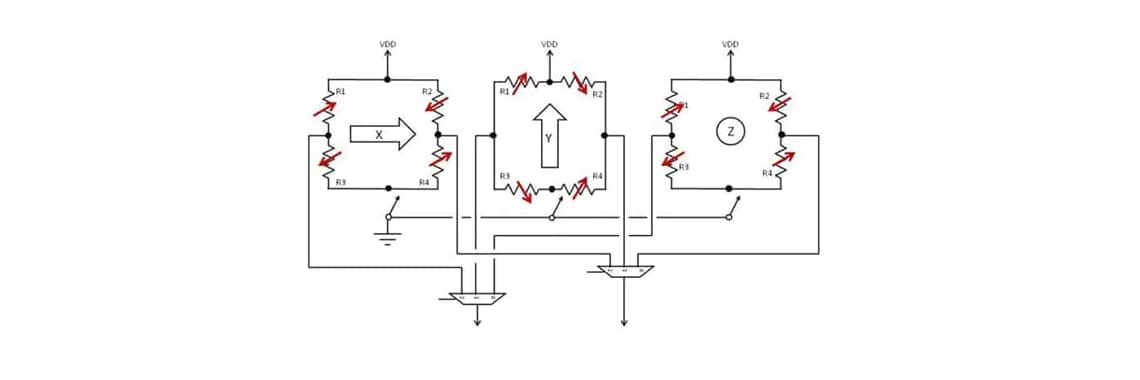

Physically, each MTJ device can be optimized to sense magnetic fields in a

specific direction. The magnetic sensor is formed by arranging arrays of

these devices into three separate Wheatstone bridges (each sensitive in

a different direction) whose output voltage can be converted to digital format

by the ADC.

Physically, each MTJ device can be optimized to sense magnetic fields in a

specific direction. The magnetic sensor is formed by arranging arrays of

these devices into three separate Wheatstone bridges (each sensitive in

a different direction) whose output voltage can be converted to digital format

by the ADC.

We’ve come a long way from that vertical force magnetometer shown in

the Royal Society transactions. The MAG3110 shown next to the thumb tack above

is 2mm x 2mm x 0.85 mm, provides measurements for all three dimensions and

consumes as little as 24 micro-amps at 1.25 Hertz sample rate. If your

microcontroller has an I2C port, you have all the circuitry you

need to take magnetic measurements.

![vertical-force-magnetometer]() I’ve obviously glossed over a lot of details. So if you’re

interested in learning more, take a look at some of the references I’ve

listed below. They do a far better and more exhaustive job at explaining your

magnetic measurement options than I can possibly provide in this space. And be

sure to visit the

MAG3110 page.

I’ve obviously glossed over a lot of details. So if you’re

interested in learning more, take a look at some of the references I’ve

listed below. They do a far better and more exhaustive job at explaining your

magnetic measurement options than I can possibly provide in this space. And be

sure to visit the

MAG3110 page.

References:

-

A New Perspective on Magnetic Field Sensing, Michael J. Caruso, Tamara Bratland, Dr. Carl H. Smith and Robert

Schneider

-

Induction coil sensors a review, Slawomir Tumanski, Measurement Science and Technology,

Institute of Physics Publishing, 2007

-

Magnetic Sensors and Their Applications, James Lenz and Alan S. Edelstein, IEEE Sensors Journal, Vol. 6, No. 3,

June 2006

-

PNI White Paper, Magneto-Inductive Technology Overview, Andrew Leuzinger and Andrew Taylor, Feb. 2010

-

Transactions – The Royal Society of Edinburgh, Volume 18, 1844

-

Magnetoresistive Sensors for Nondestructive Evaluation, Albrecht Jander, Carl Smith and Robert Schneider, 10th SPIE

International Symposium, Nondestructive Evaluation for Health Monitoring and

Diagnostics,

-

Magnetometer Wikipedia Article

163 years later, we have technologies for taking magnetic measurements based

on any number of physical phenomena and targeted at almost any range of

measurement needed. With names like AMR, GMR, TMR, Squid, fluxgate,

magneto-inductive, SERF and Caesium vapor, it’s easy to get confused.

If you are working in the consumer area, you can probably rule out most of

these.

163 years later, we have technologies for taking magnetic measurements based

on any number of physical phenomena and targeted at almost any range of

measurement needed. With names like AMR, GMR, TMR, Squid, fluxgate,

magneto-inductive, SERF and Caesium vapor, it’s easy to get confused.

If you are working in the consumer area, you can probably rule out most of

these.

Magneto-inductive sensors, like those offered by

Magneto-inductive sensors, like those offered by

Physically, each MTJ device can be optimized to sense magnetic fields in a

specific direction. The magnetic sensor is formed by arranging arrays of

these devices into three separate Wheatstone bridges (each sensitive in

a different direction) whose output voltage can be converted to digital format

by the ADC.

Physically, each MTJ device can be optimized to sense magnetic fields in a

specific direction. The magnetic sensor is formed by arranging arrays of

these devices into three separate Wheatstone bridges (each sensitive in

a different direction) whose output voltage can be converted to digital format

by the ADC.