Author

NXP

At NXP, innovation is always now, but our focus is always the future. Our dedicated team of experts is united by a passion to make everyday life more remarkable through technologies that continually redefine life as we know it.

We’ve all had the experience of buying fresh fruit and vegetables from the supermarket only to find a day or two later that the produce has gone bad and has to be thrown away. Well, imagine that scenario, but on a massive scale. Managing perishable goods is not just a major issue for consumers. It is even a more important issue for manufacturers, transporters and retailers since food and pharmaceutical goods are going to increasingly long and complex supply chains with many dangers of poor temperature control, delays and physical mishandling.

The annual global waste of perishable goods is huge. According to a recent report published by the Institution of Mechanical Engineers, as much as half of all the food produced in the world – equivalent to 2bn tonnes – never makes it onto our plates. And almost half of the food that is bought in Europe and the US is thrown away by consumers and retailers because its physical appearance doesn’t meet our exacting standards. Transporting and distributing fresh foods and ensuring that they remain in a condition that satisfies consumers remains a huge challenge. In fact, market research indicates that the food industry discards as much as €25bn a year in spoiled goods. But improving and controlling conditions such as temperature and humidity during transit can play a huge role in delivering longer-lasting produce to the consumer.

With today’s technology we can optimize the supply chain based on the expiration date, by following the entire process perishable goods are going through. It is possible to constantly measure conditions and quality of products and controlling these conditions at the same time (temperature, humidity, pH and light). By having these insights and skills we can make better decisions in the supply chain. In believe we need to be much more thoughtful in the decision making processes within the supply chain if we really want to reduce the waste of food.

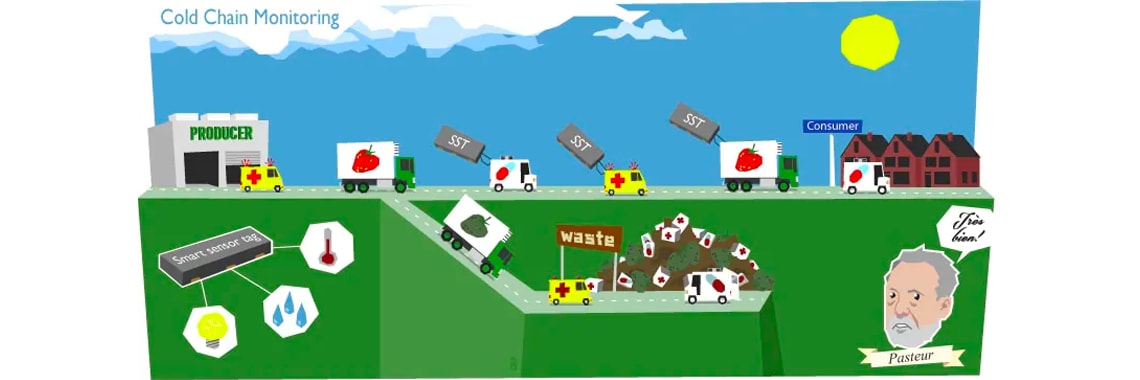

One way of tackling this challenge is to implement a monitor and control system in the logistic chain, which consists out of multiple sensor tags, middleware (such as gateways), and network connection to web-interface and to a cloud. NXP can penetrate this emerging market with multiple existing technologies, such sensor IC’s, communication ICs (NFC, RFID, etc.), microcontrollers for wireless sensor nodes and the Automotive Telematics On-board unit Platform (ATOP) as a gateway. It is key that the specific application development is carried out with existing players in this market (such as Motorola, IBM, etc.) and the focus should be on interoperability and reconfigurability of the embedded system since this will lead to a lower cost-of-ownership and wider application range.

In partnership with 15 industrial and academic partners, NXP developed a sensor tag and did several trials with this technology to improve the cold chain monitoring at all levels of the supply chain within the PASTEUR Project. Combining radio frequency identification (RFID) with multiple sensors, the tag attaches to bulk transportation containers and gives a realistic, continuously updated estimate of how long the food they contain will stay fresh. This could help food distributors optimize their supply chain to minimize the amount of food that is spoiled before it reaches the retailer.

The results of the PASTEUR project were recently presented at the International Conference on Sustainability and the Cold Chain and discussed the capabilities of our multi-sensory chip used in the PASTEUR Project, the SEN-300. The chip was attached to food packaging in order to detect and communicate changes in temperature, humidity and pH levels of products, assign liability and initiate preventative measures to guarantee the quality of produce available to the consumer.

We believe that NXP chip solutions (such as the SEN-family and wireless chipsets) are ready to be introduced in packaging such as boxes, crates and pallets and can play an important role in reducing the global waste of perishable goods. Given the size and global nature of supply chains, we see more collaboration as an opportunity for technology in the cold chain. If we really want to reduce the enormous waste of perishable goods, collaboration between suppliers, logistics and academic parties is needed to present optimal in the future, since the potential market is enormous! I think the first markets to be addressed will be the high-value goods (for example, pharmaceuticals) and critical delivery items (for example, organs). Most perishables only need temperature, relative humidity and light monitoring and control in some cases and this is what we can do immediately with our new sensor product. Nowadays, in case passive temperature loggers are used for pharmaceuticals, the entire batch is disposed when it goes over a certain temperature, irrespective of the time of exposure. Here we can win a lot. What is your vision about which markets of perishable goods should be addressed first with our available technologies? I’d really appreciate your thoughts and input on this global issue.

Update October 24 – NXP Semiconductors and Wageningen University & Research Center won the 2013 Food Valley Award for the development and demonstration of the Pasteur Sensor Tag. Food Valley, the Netherlands, awards an annual prize to the most distinctive project or initiative in the agrifood business. Judging criteria are the innovative character of the project, the degree of (innovative) cooperation, the economic viability and the overall attention to Corporate Social Responsibility.

Tags: Technologies

At NXP, innovation is always now, but our focus is always the future. Our dedicated team of experts is united by a passion to make everyday life more remarkable through technologies that continually redefine life as we know it.

July 15, 2020

by Tom Pannell

July 28, 2020

by Markus Levy

August 4, 2020

by Ron Martino