EV Motor Control Development Kits

Contents of this document

-

Out of the Box

-

Get Software

-

Plug It In

-

Build, Run

Sign in to save your progress. Don't have an account? Create one.

Purchase your S32K396 BLDC/PMSM Development Kit

1. Out of the Box

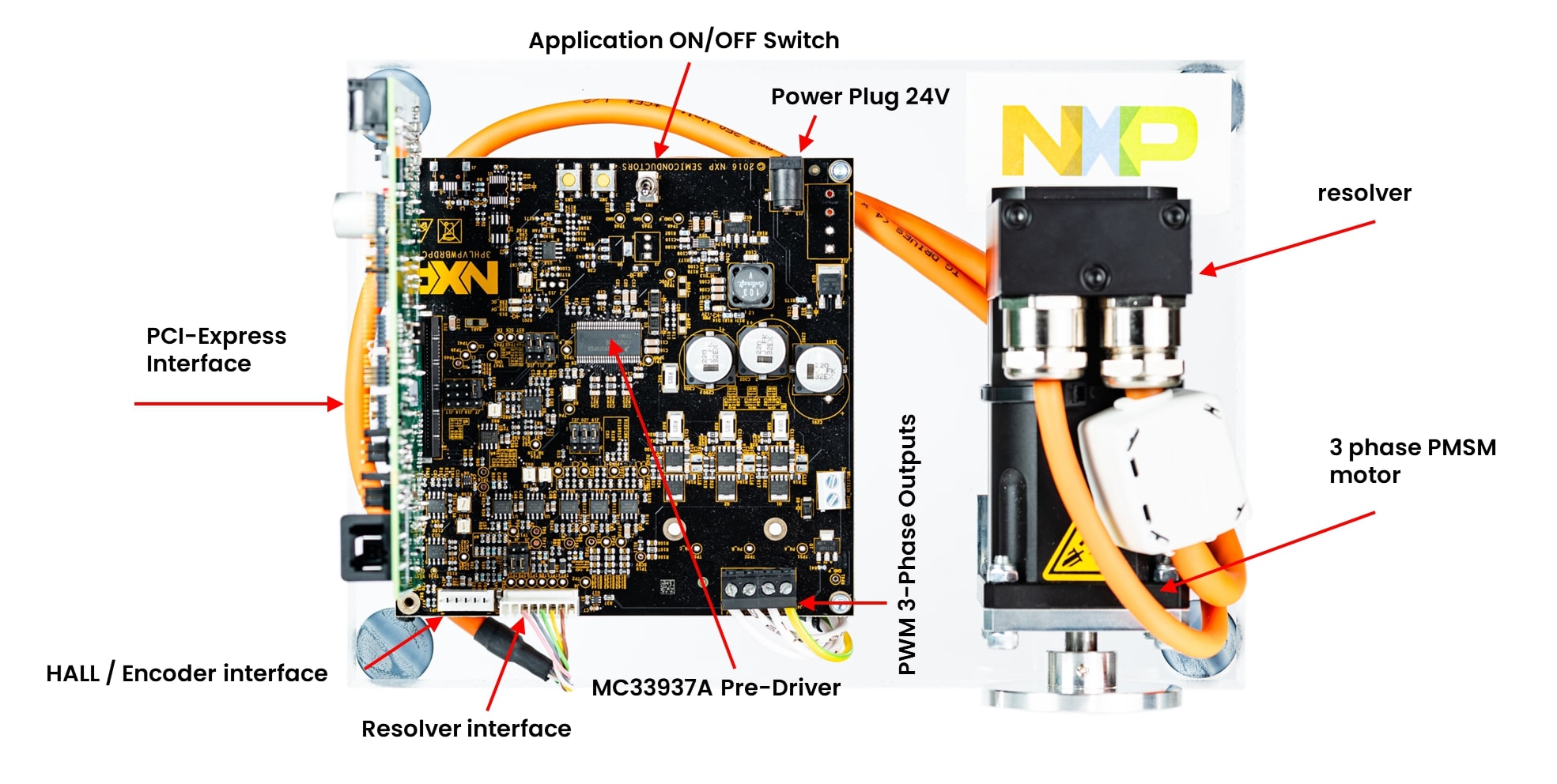

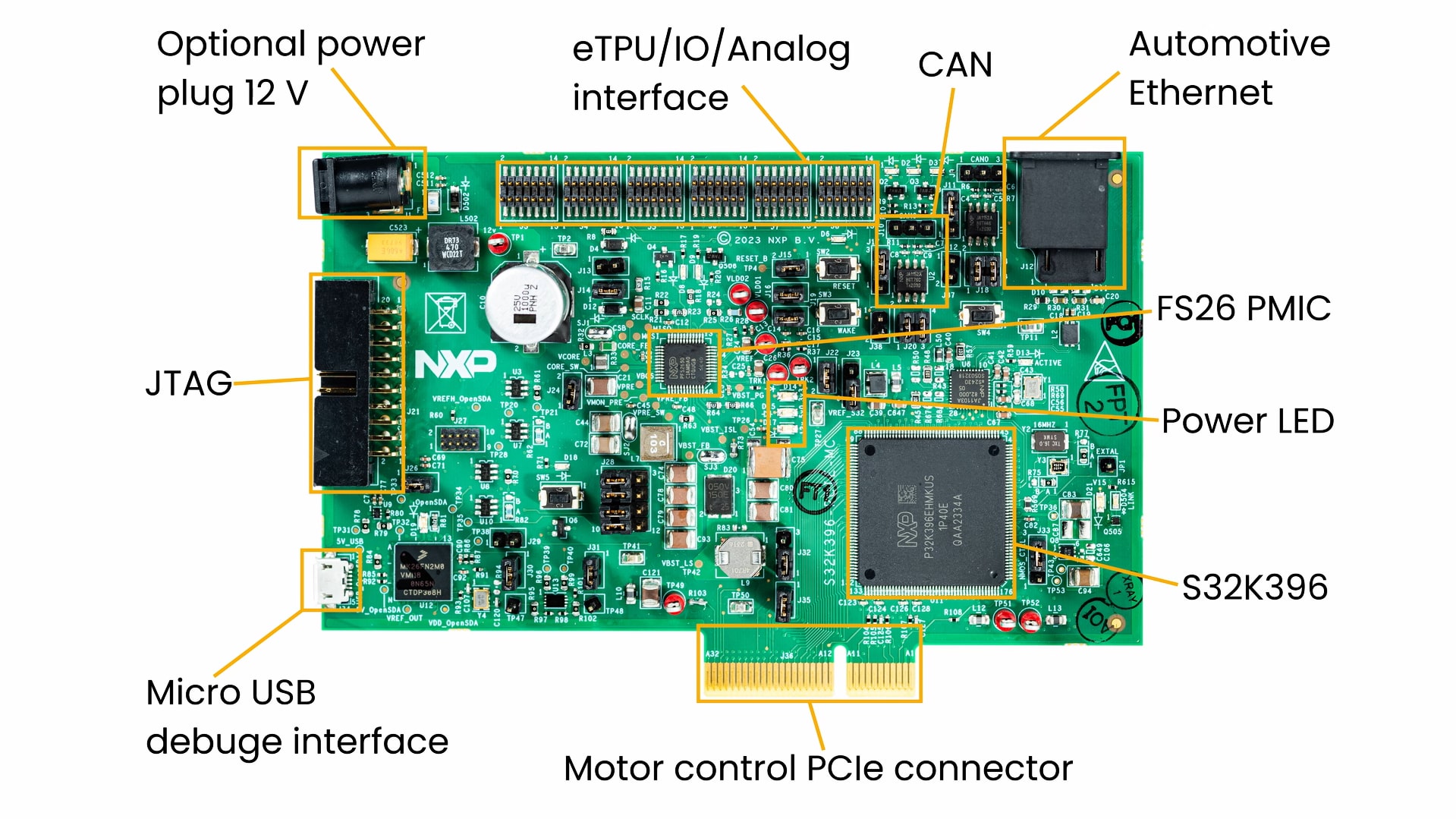

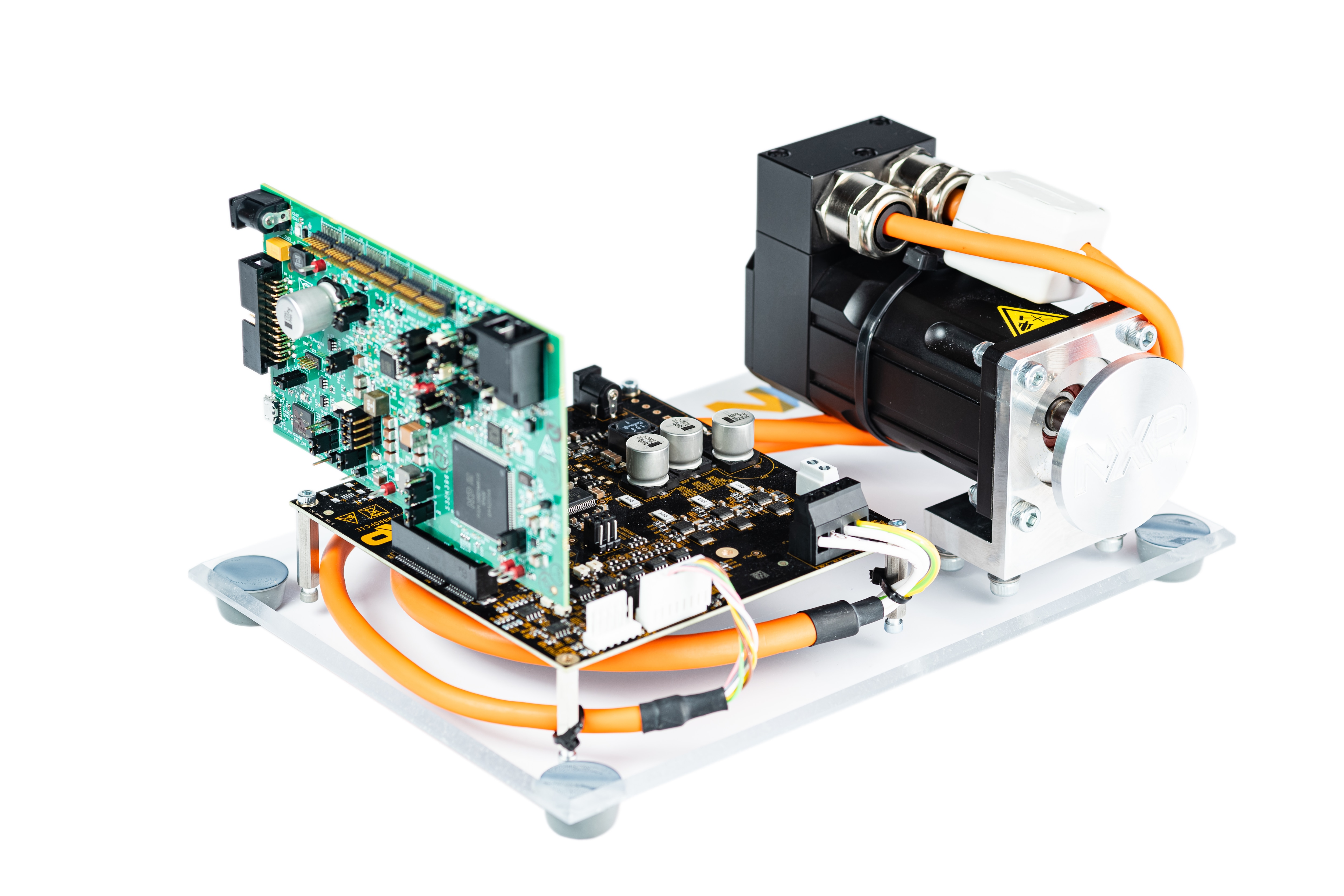

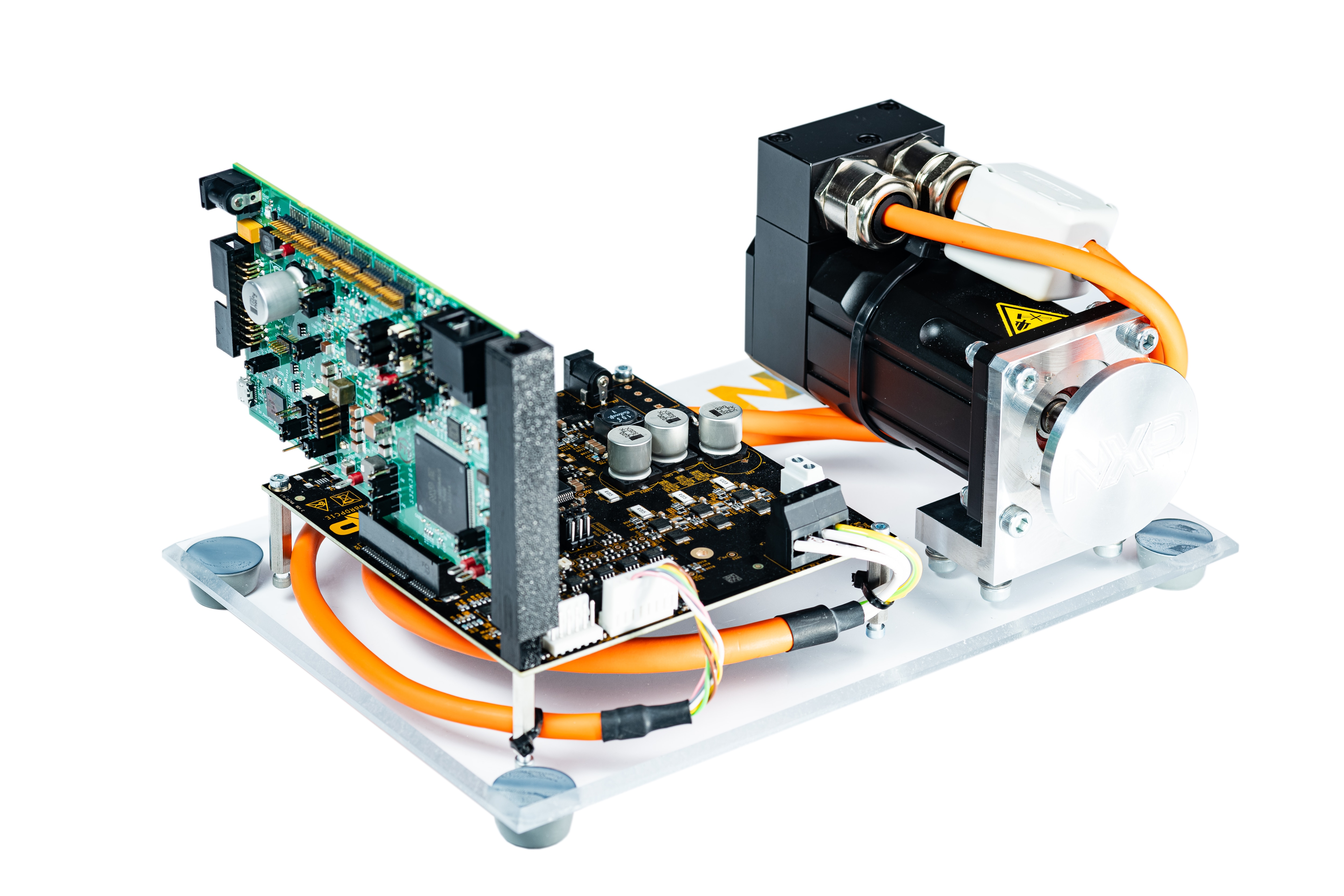

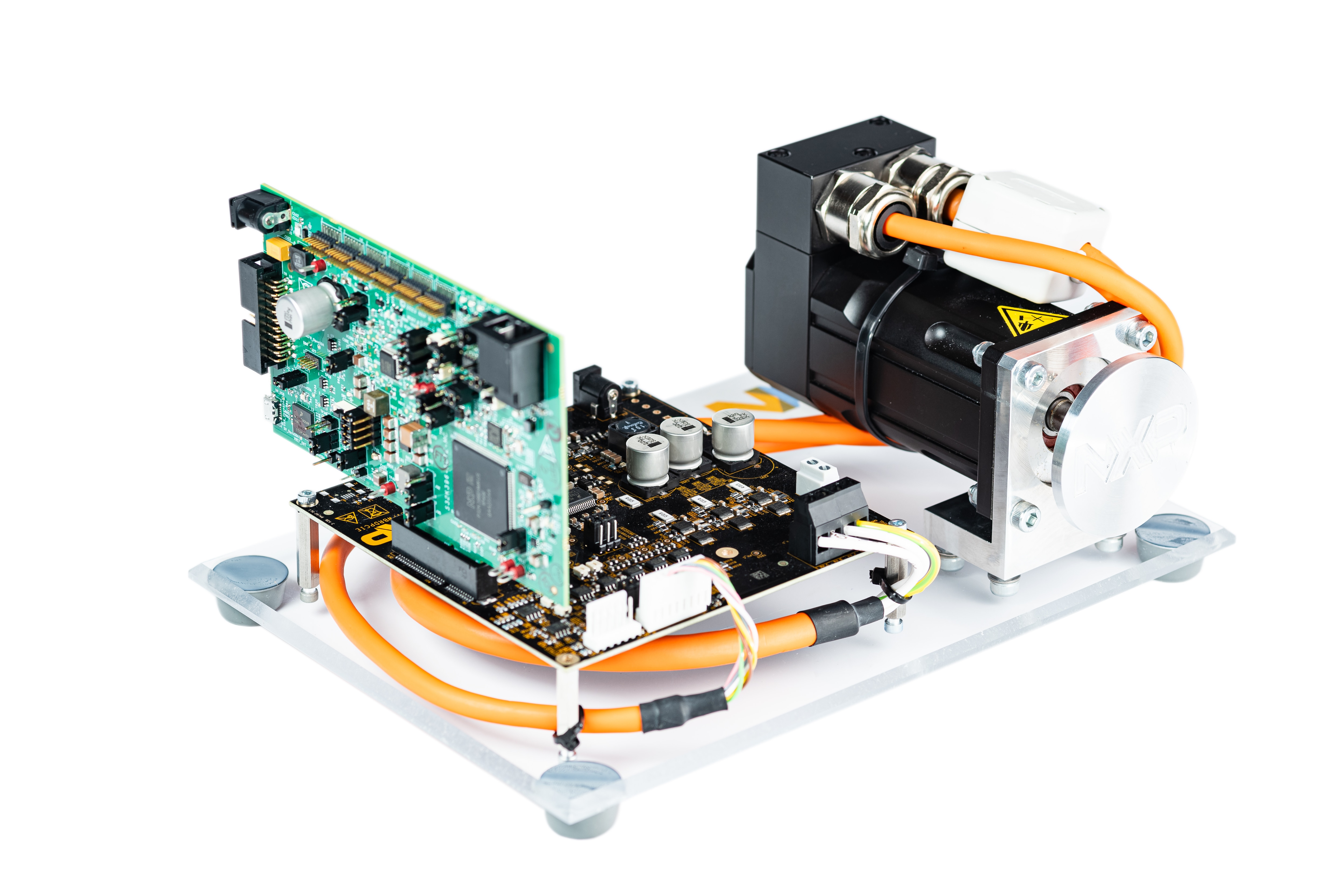

NXP's MCSPTR2AK396 Low-Voltage Motor Control Development Kit is designed for customers developing low-voltage motor control applications using the S32K396 automotive microcontroller.

This page will guide you through the process of setting up and using the 3-Phase Permanent Magnet Synchronous Motor Control Development Kit with S32K396 (MCSPTR2AK396).

1.1 MCSPTR2AK396 Overview

- S32K396-PCIe controller board

- 3-phase PMSM/BLDC low-voltage power stage based on the MC33937A pre-driver integrated circuit

- Micro USB cable

- +24 VDC power supply

- Universal adapter

- PSE power cord

- 3 phase PMSM motor with resolver, 30 V per phase, 3000 RPM, 0.32 Nm, 95 W, 5.2 A

2. Get Software

Sign in at nxp.com with your credentials.

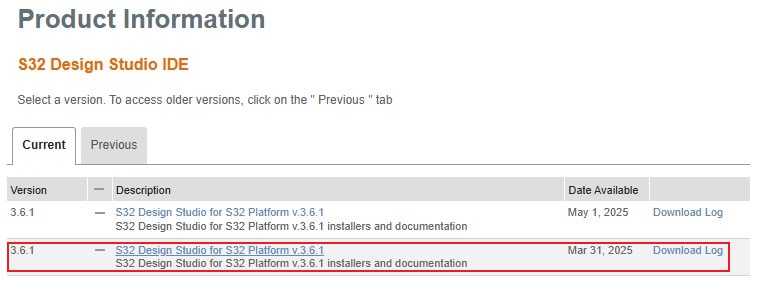

2.1 Get S32 Design Studio for S32 Platform IDE

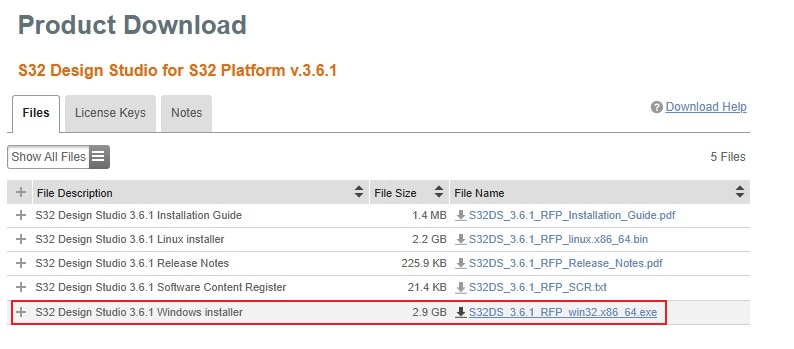

Download and Install S32 Design Studio for S32 Platform.

2.2 Downloading the Real-Time Drivers (RTD)

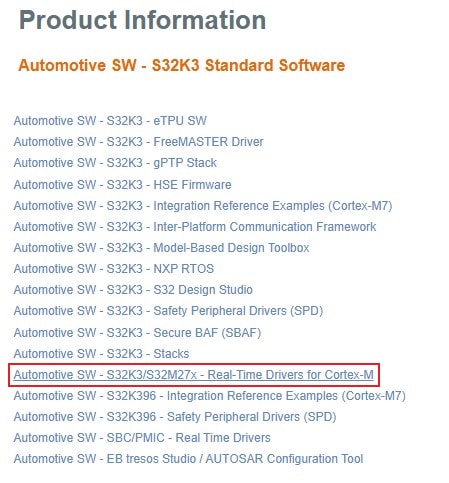

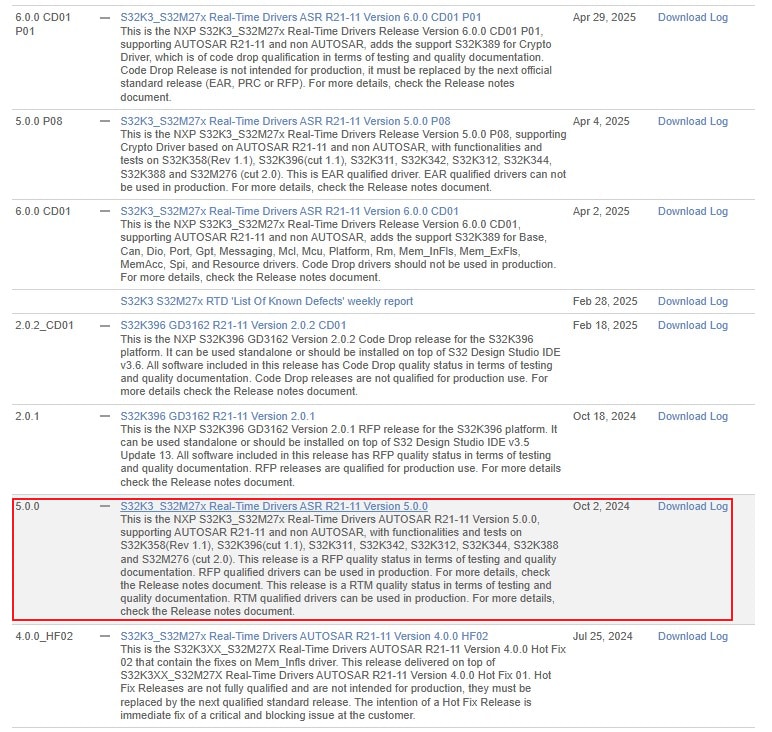

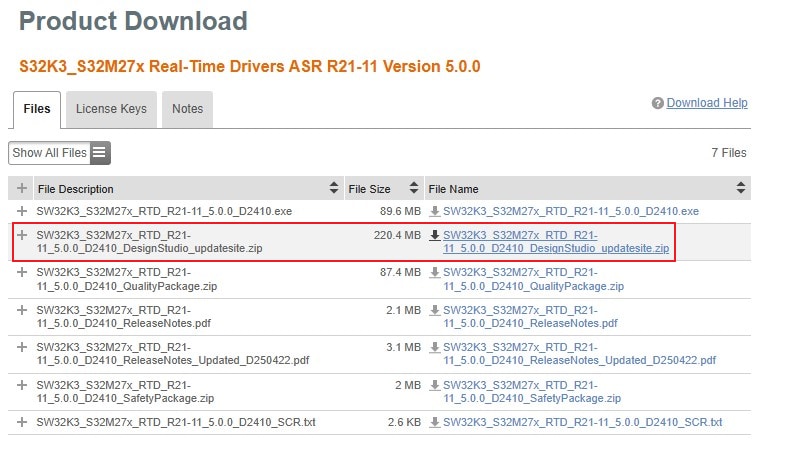

Download S32K3_S32M27x Real-Time Drivers ASR R21-11 Version 5.0.0.

2.3 Install the RTD drivers

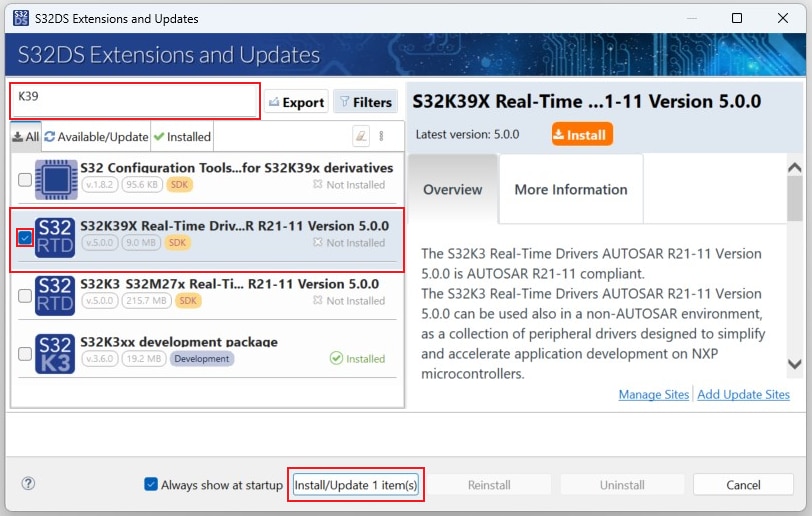

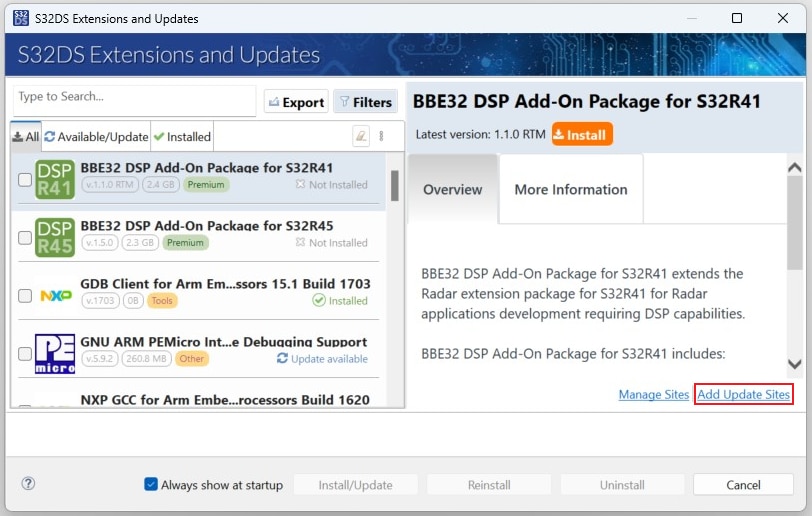

In S32DS, go to Help → S32DS Extensions and Updates from the top menu to open the S32DS Extensions and Updates dialogue.

Click Add Update Sites and browse for the downloaded RTD *.zip file.

Find, select and install S32K39X Real-Time Drivers ASR R21-11 Version 5.0.0.

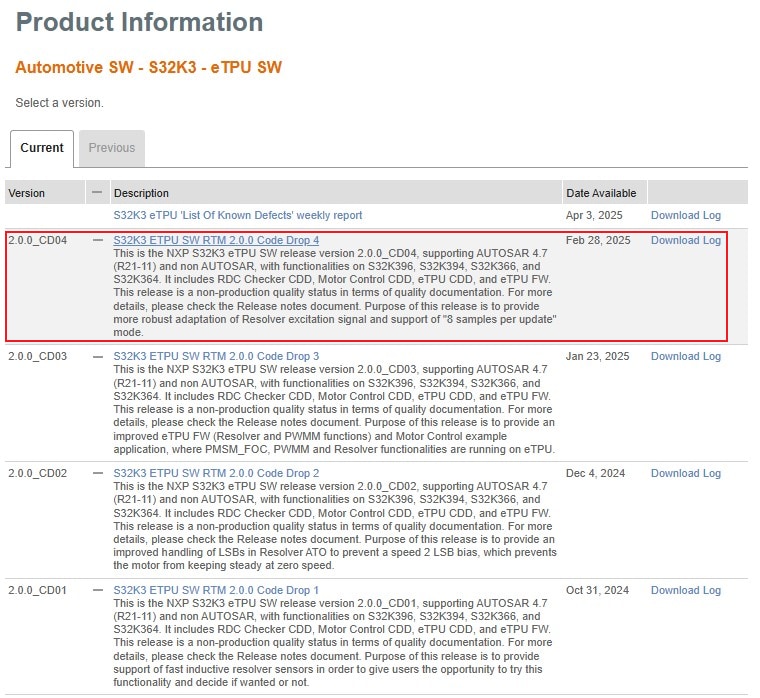

2.5 Install eTPU SW

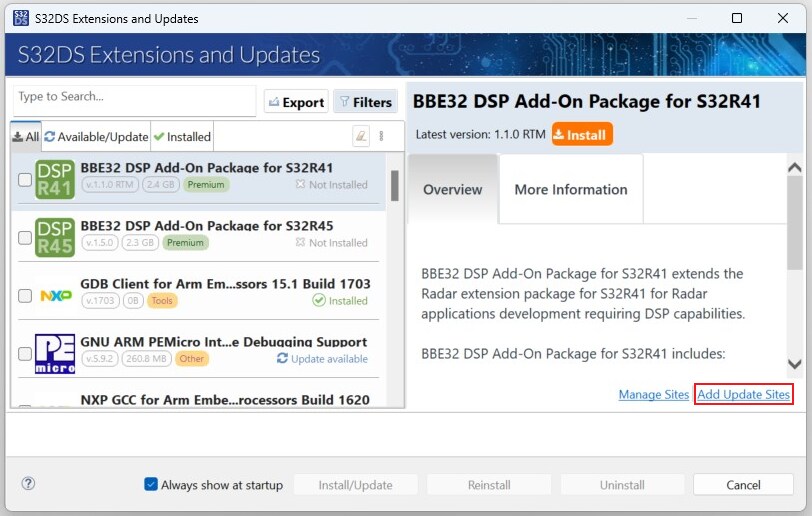

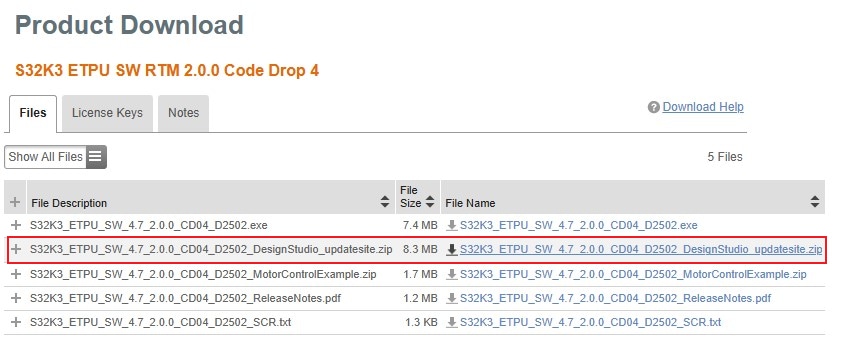

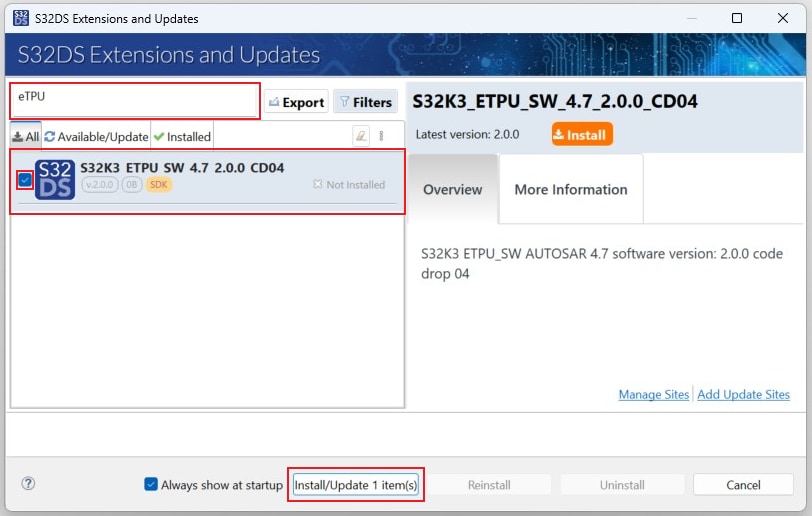

In S32DS, go to Help → S32DS Extensions and Updates from the top menu to open the S32DS Extensions and Updates dialogue.

Click Add Update Sites and browse for downloaded eTPU SW updatesite file.

Select and install eTPU SW.

2.6 Install FreeMASTER Communication Driver

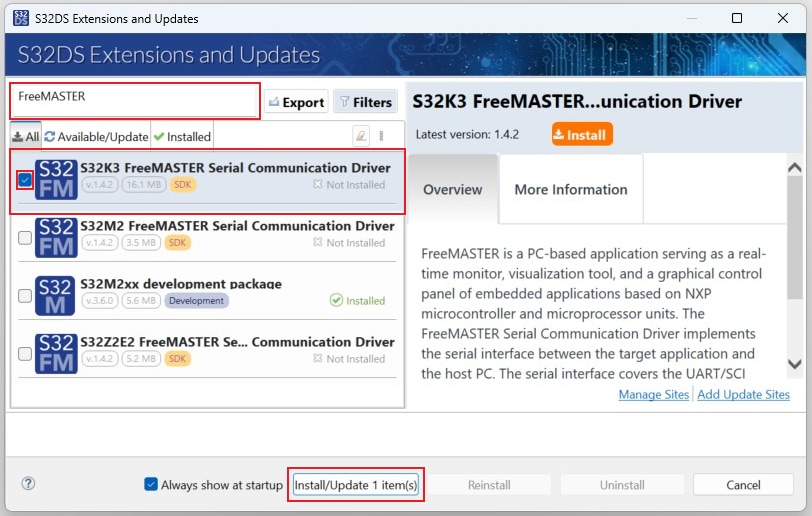

In S32DS, go to Help → S32DS Extensions and Updates from the top menu to open the S32DS Extensions and Updates dialogue.

Select and install FreeMASTER Communication driver.

2.8 Get AMMCLib for S32K3

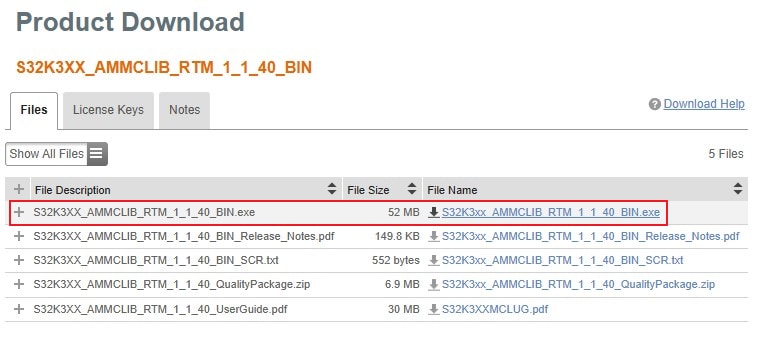

Download and install latest Automotive Math and Motor Control Library set for S32K3.

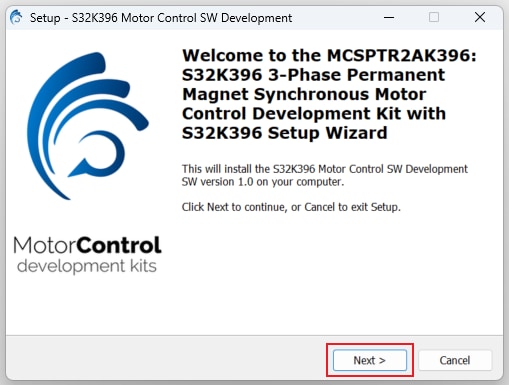

2.9 Get the MCSPTR2AK396 Motor Control Application Software

Download and install the MCSPTR2AK396 motor control application software .

If not, install AMMCLib and reinstall the EV-INVERTERGEN3 motor control application software. That will simplify the next project import (paths to the latest AMMCLib will be already updated).

3. Plug It In

3.1 Check Default Jumper Positions

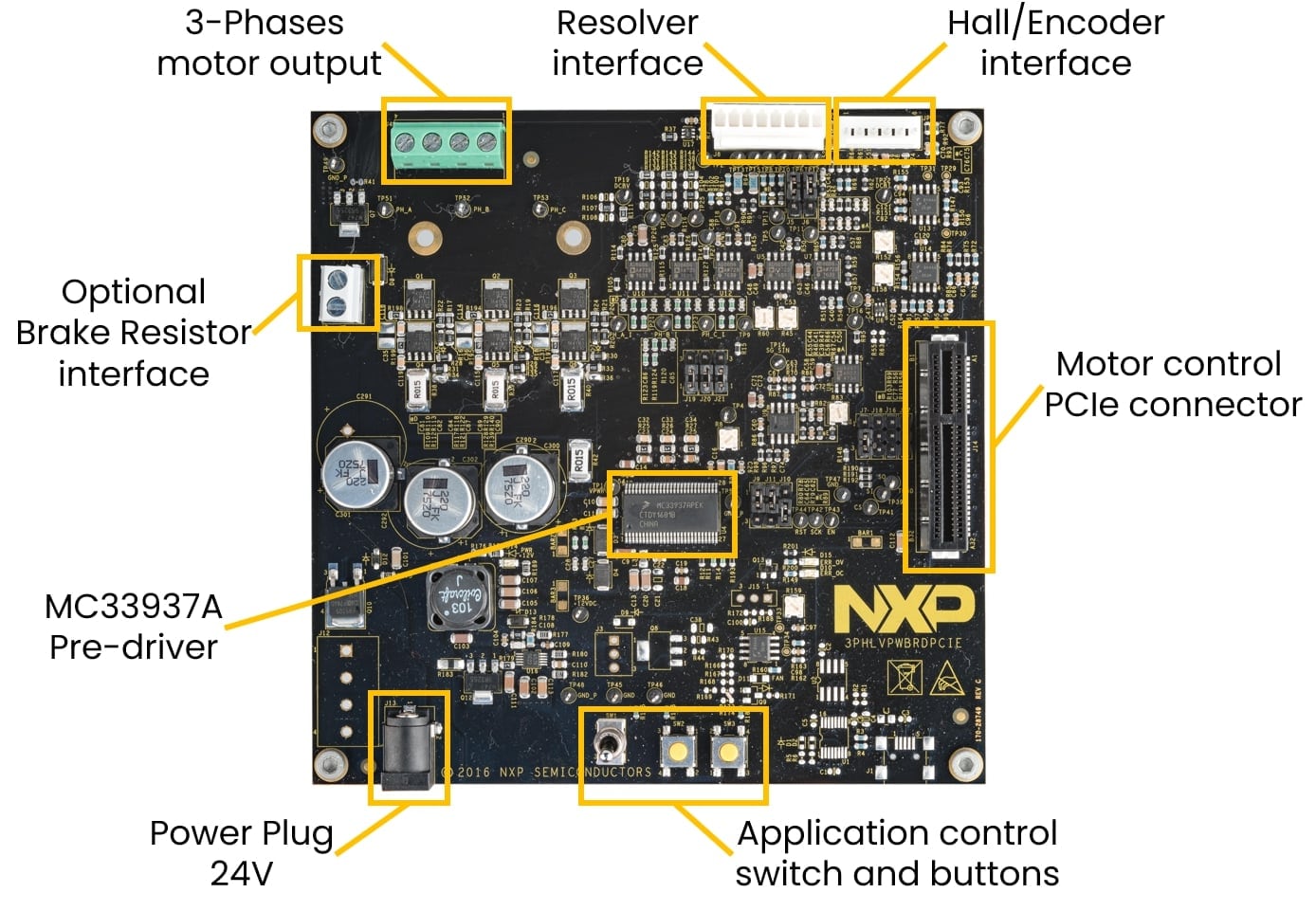

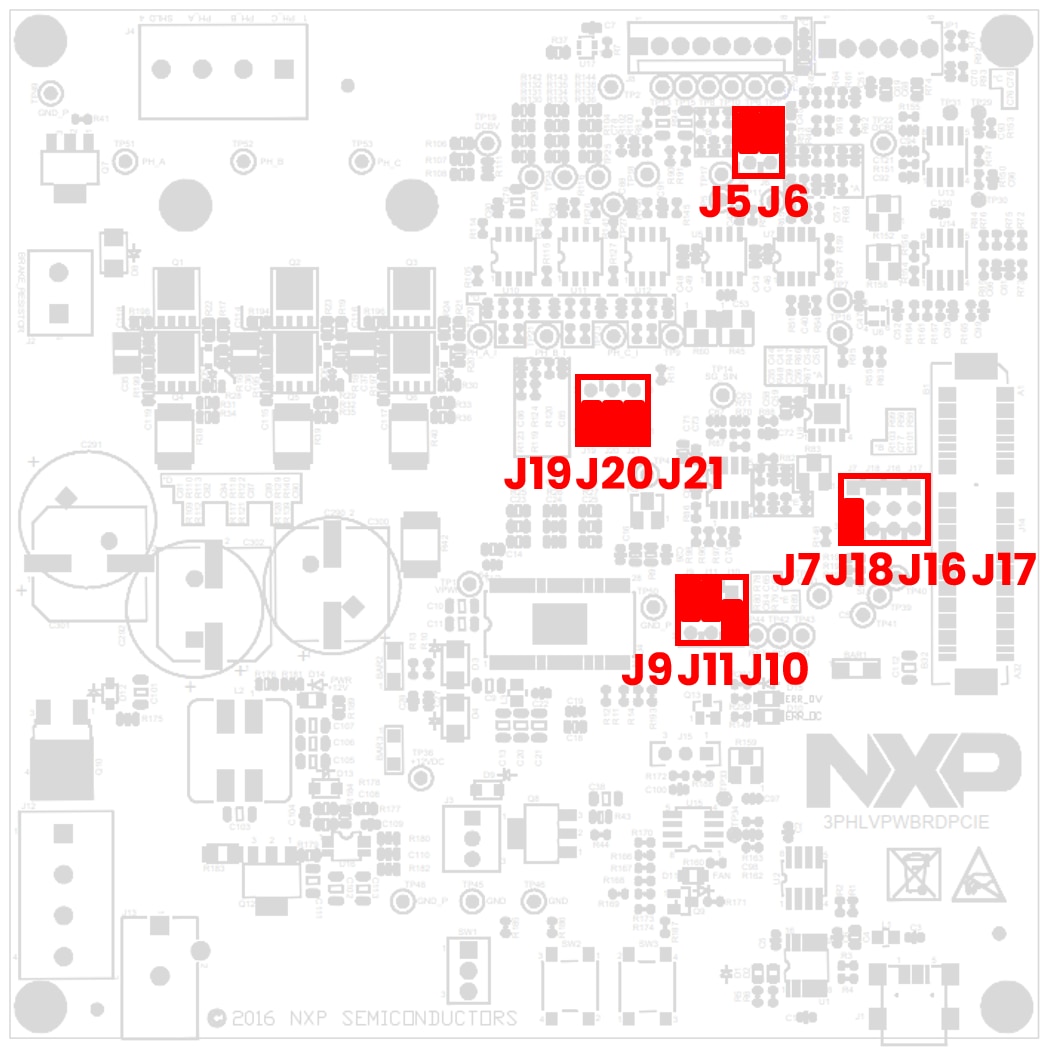

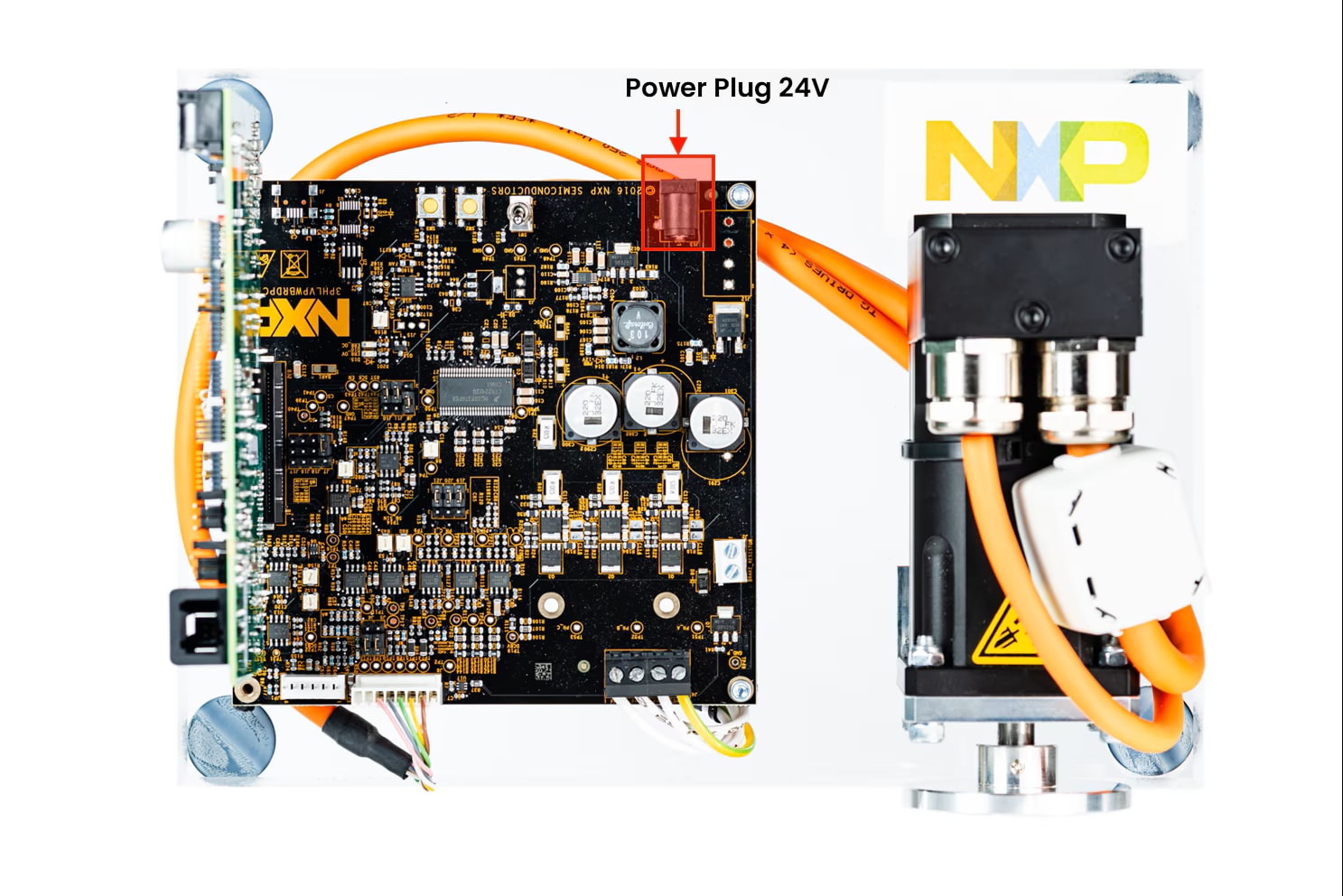

Check the default jumper positions at the 3PHLVPWBRDPCIE power stage board

| 3PHLVPWBRDPCIE Default Jumper Settings | ||

|---|---|---|

| Jumper | State | Notes |

J5 |

2-3 | Resolver S4 output routed to operational amplifier |

J6 |

2-3 | Resolver S3 output routed to operational amplifier |

J7 |

2-3 | Resolver excitation signal from TM5 signal at PCIe connector |

J9 |

1-2 | DC BUS current sensing signal measured via operation amplifier |

J10 |

2-3 | VREF as voltage source for overcurrent threshold potentiometer |

J11 |

1-2 | External overcurrent fault comparator |

J16 |

OPEN | Zero-Cross detection disconnected |

J17 |

OPEN | Zero-Cross detection disconnected |

J18 |

OPEN | Zero-Cross detection disconnected |

J19 |

1-2 | Phase A current signal routed to AN1 signal at PCIe connector |

J20 |

1-2 | Phase B current signal routed to AN3 signal at PCIe connector |

J21 |

1-2 | Phase C current signal routed to AN5 signal at PCIe connector |

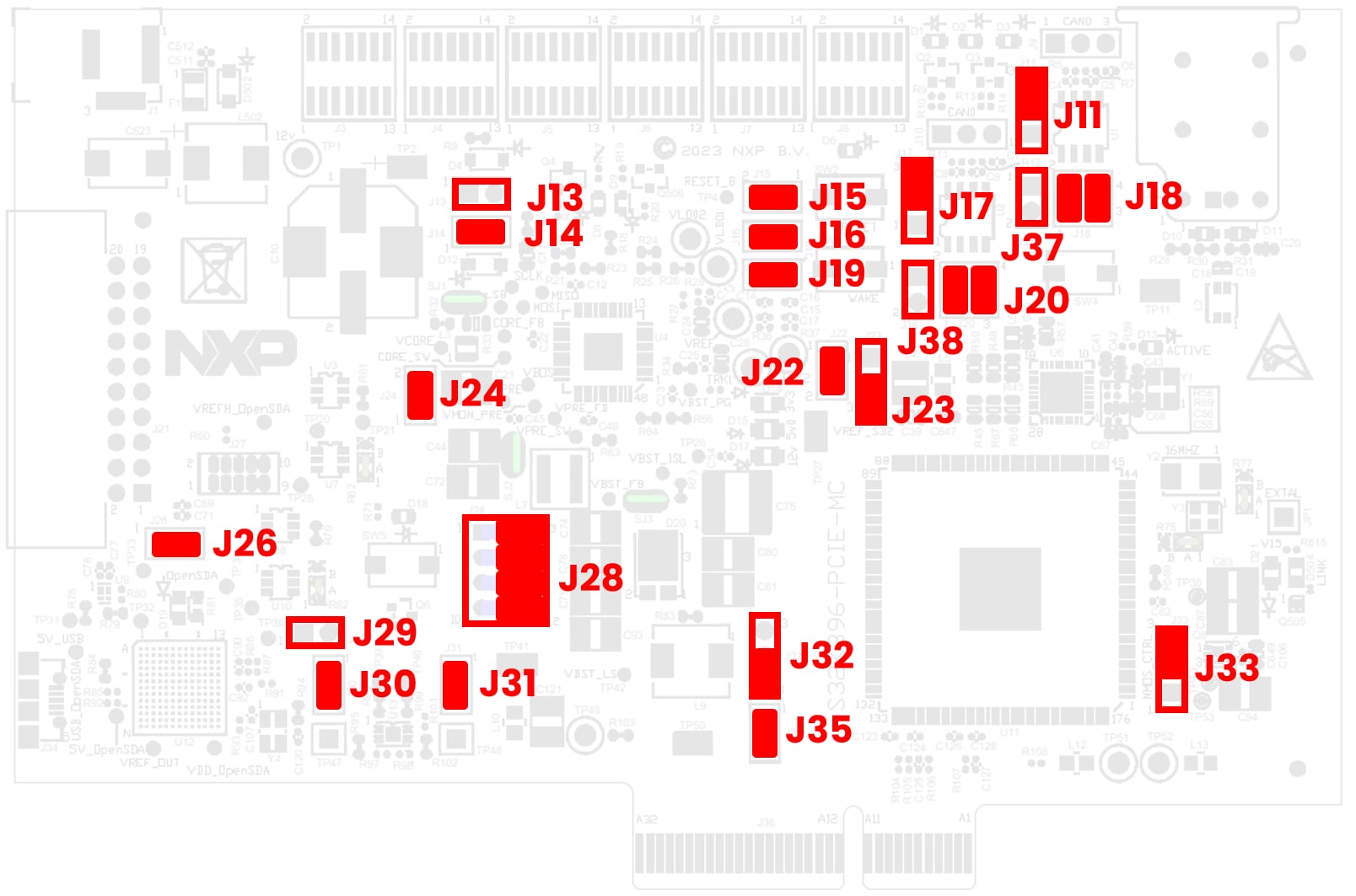

Check the default jumper positions at the S32K396-PCIE-MC controller board

| S32K396-PCIE-MC Default Jumper Settings | ||

|---|---|---|

| Jumper | State | Notes |

J11 |

2-3 | CAN0 Transceiver STB signal pulled down |

J13 |

OPEN | FS26_VDEBUG signal generated - FS26 starts in debug mode |

J14 |

CLOSED | FS26_VDEBUG signal derived from VBOS signal |

J15 |

CLOSED | RESET SW2 connected to RESET_B signal |

J16 |

CLOSED | External wake-up signal connected to MCU |

J17 |

2-3 | CAN3 Transceiver STB signal pulled down |

J18 |

1-2, 3-4 | CAN0_TX and CAN0_RX signals routed to on-board CAN transceiver |

J19 |

CLOSED | Functional Safety signals FS0B and FS1B connected |

J20 |

1-2, 3-4 | CAN3_TX and CAN0_RX signals routed to on-board CAN transceiver |

J22 |

CLOSED | RESET_B signal connected as wake-up signal to FS26 |

J23 |

2-3 | VHREF_H voltage connected to VDD_HV_A |

J24 |

CLOSED | RESET_B signal connected to 20-pin JTAG connector |

J26 |

CLOSED | VDD_JTAG signal present at 20-pin JTAG connector |

J28 |

2-3, 5-6, 8-9, 11-12 | JTAG signals routed to S32K3 on-board debugger |

J29 |

OPEN | External RESET signal pins |

J30 |

CLOSED | LPUART2_TX signal connected to S32K3 on-board debugger |

J31 |

1-2 | LPUART2_RX signal connected to S32K3 on-board debugger |

J32 |

1-2 | Sine Wave Generator 1 routed to TM5 signal at PCIe connector |

J33 |

2-3 | V15 voltage regulated by external NMOS transistor |

J35 |

CLOSED | PTB11 connected to TM3 signal at PCIe connector |

J37 |

OPEN | CAN0 Transceiver STB signal not connected to MCU |

J38 |

1-2 | CAN3 Transceiver STB signal not connected to MCU |

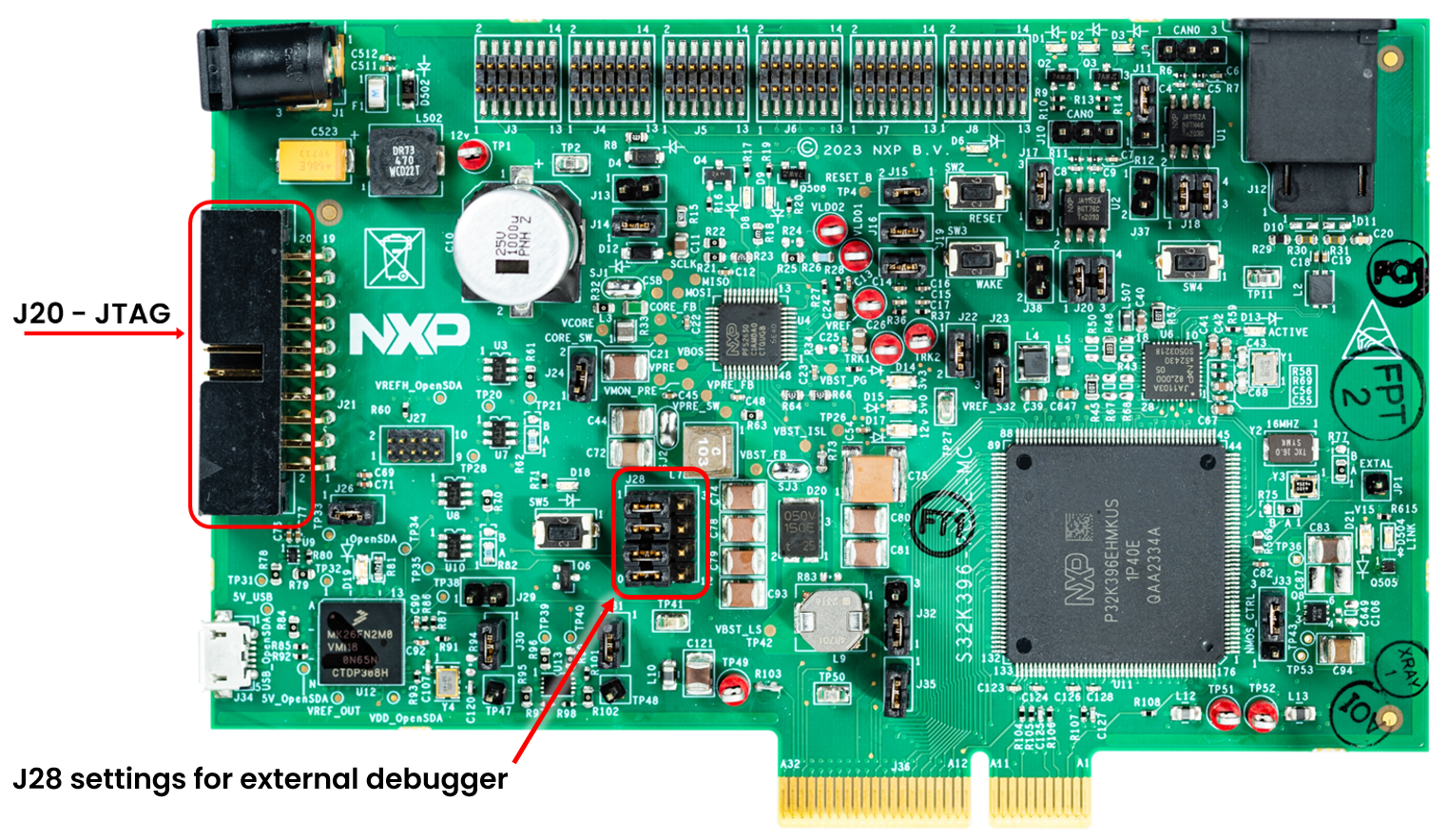

In case of using an external JTAG debug probe via J20 connector, change the settings of J28 to 1-2, 4-5, 7-8, 10-11.

3.2 Assemble the Boards

To assemble the controller board to the power stage board, connect the board to the PC with a micro USB cable

Optionally use the support column for improving mechanical robustness

4. Build, Run

Let's take your MCSPTR2AK396 motor control kit for a test drive.

4.1 Select Application and Project Import

Select the appropriate PMSM motor control application from the installed directory.

NXP\MC_DevKits\MCSPTR2AK396

To import the installed application software project in the S32 Design Studio IDE for S32 Platform:

- Launch S32DS for S32 Platform

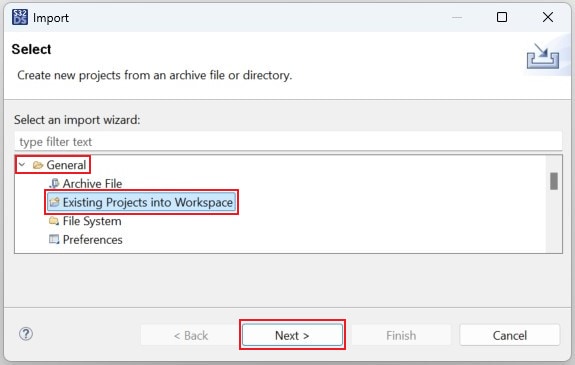

- Go to File → Import, then select General → Existing Projects into Workspace

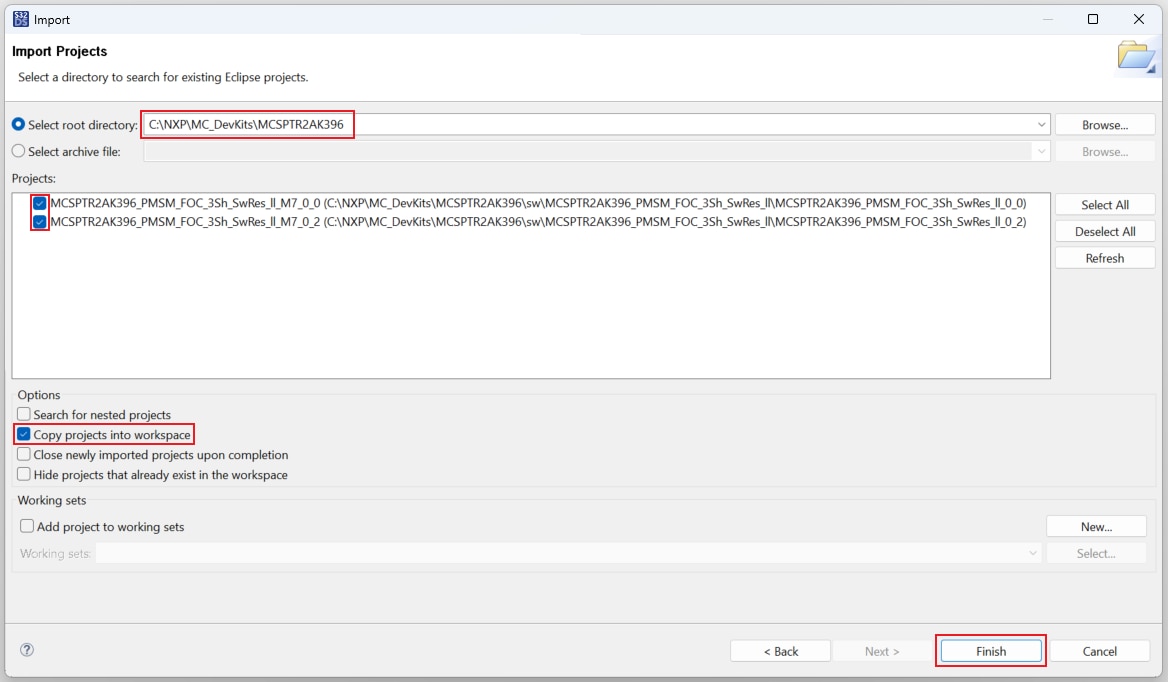

- Navigate to the installed application directory:

NXP\MC_DevKits\MCSPTR2AK396, click Select Folder. Next, check the box for the option Copy project into workspace. Then, click Finish - Afterward, a new window will appear. First for the

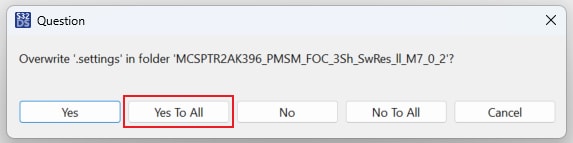

M7_0_0project, then for theM7_0_2project. Click Yes To All to overwrite '.settings' folder in both project directories

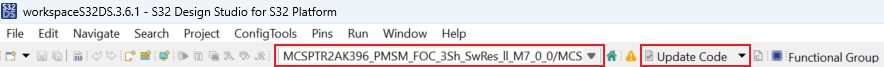

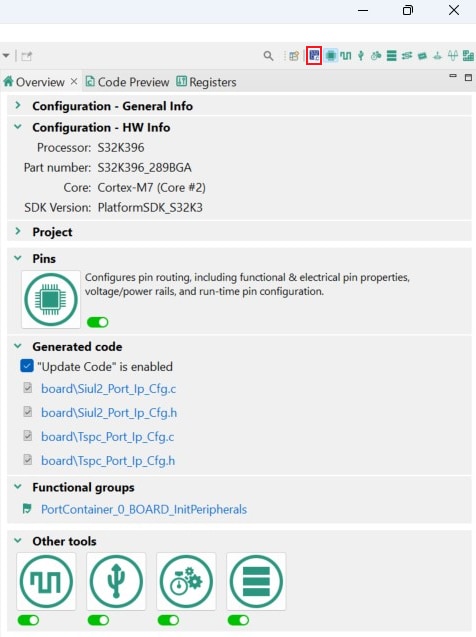

4.2 Use Configuration Tool

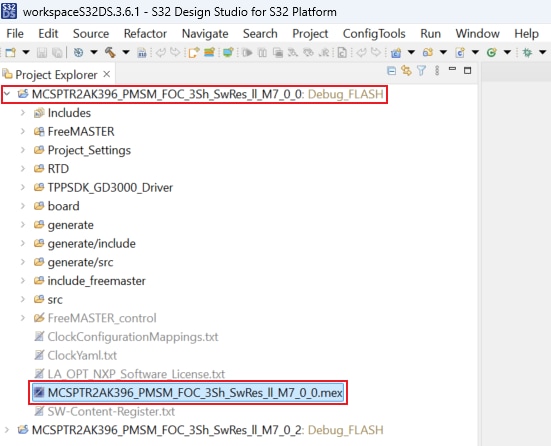

- Unfold the structure of the first project and double-click on

*.mexfile to open the project configuration in S32 Configuration Tool - Ensure that you are configuring the

M7_0_0project, and click Update Code button for generating configuration files. Next, in S32 Configuration Tool, click the pop down button next to the project name and choose *.mex file for theM7_0_2project. Click Update Code accordingly

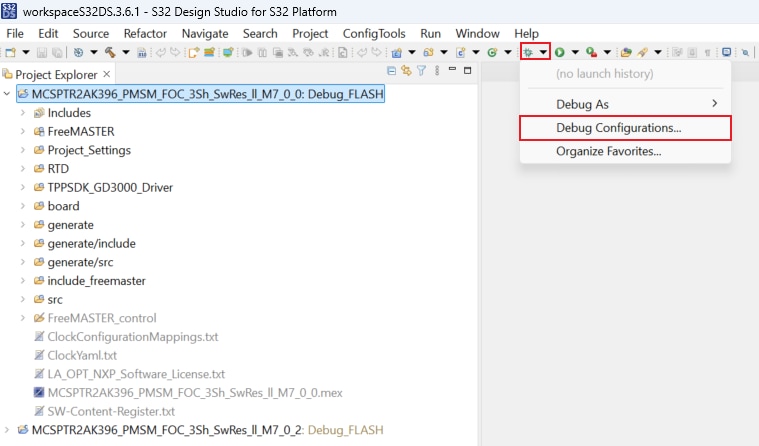

4.3 Upload Software and Debug

- In S32DS, return back to the C/C++ perspective by clicking the button located in the upper-right corner

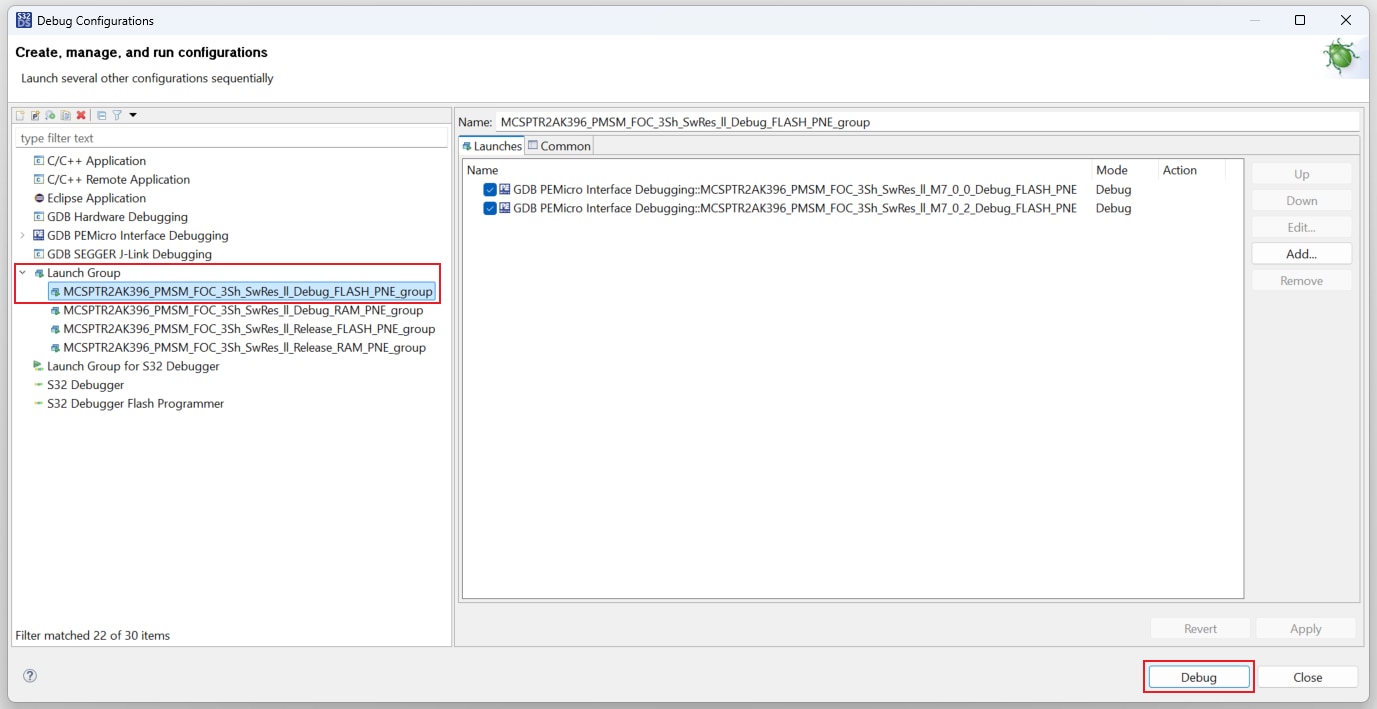

- Click Debug As menu and select Debug Configurations

- Next, expand Launch Group and click the first launch configuration. This configuration will upload both the

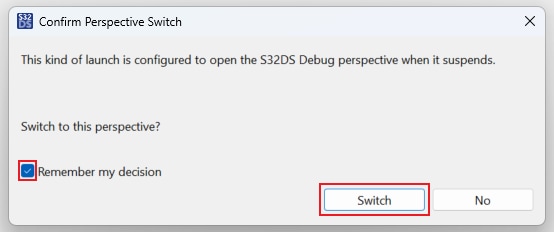

M7_0_0andM7_0_2projects to the MCU. Click Debug for building and uploading software into MCU - Afterwards, a new window will appear. Check the box for the option Remember my decision and click Switch

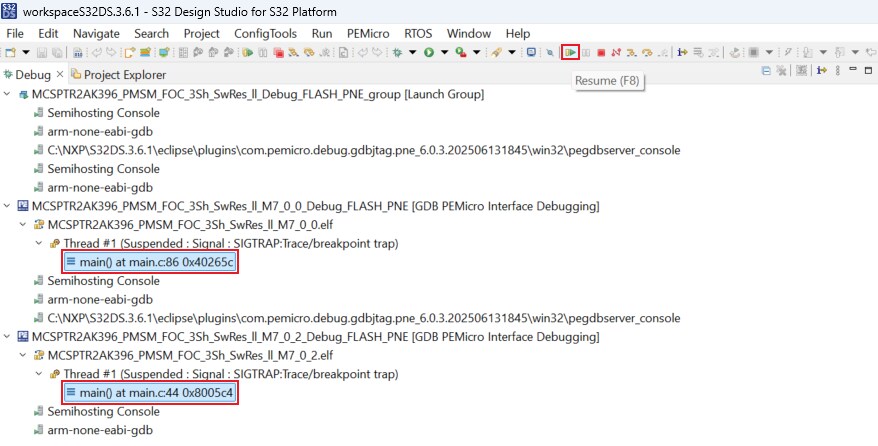

- The S32DS will switch into debug perspective. First, press Ctrl + click both project main() files to highlight them. Next, let both projects run by clicking Resume (or press

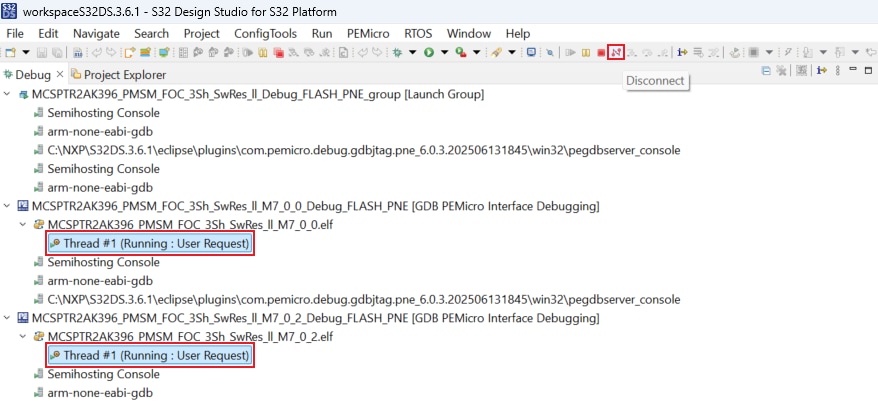

F8) - Click Disconnect to avoid interference between the S32DS IDE debugger and the FreeMASTER tool

4.4 Set Up the Debugging Tool

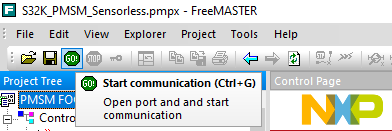

Launch the FreeMASTER application.

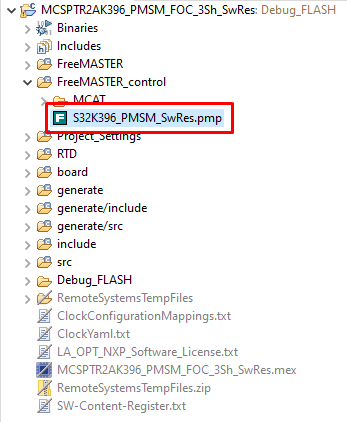

To open the *.pmpx FreeMASTER project <selected project>\FreeMASTER_control, click File → Open Project.

To enable communication, in the FreeMASTER toolbar, click Go (or press Ctrl + G).

Successful communication displays in the status bar at the bottom as: RS-232 UART Communication;COMn;speed = 115200.

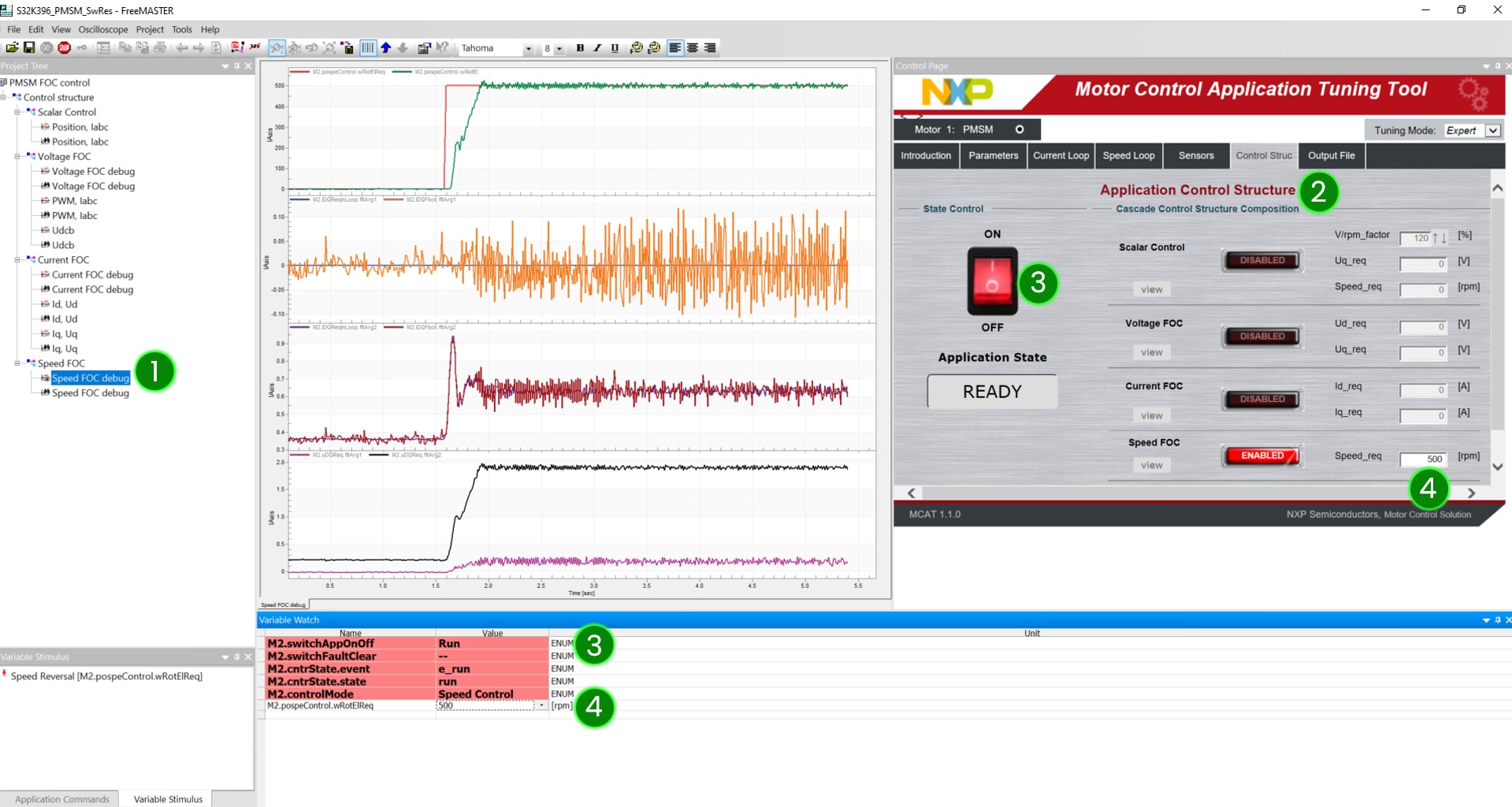

Application Control

Controlling the Application

To spin the motor:

- Select the Speed FOC debug view from the project tree

- Switch to the Control Struct tab in the Motor Control Application Tuning (MCAT) tool tab

- Switch application ON either in MCAT or in variable watch window

- Set the required speed either in MCAT or in the variable watch window

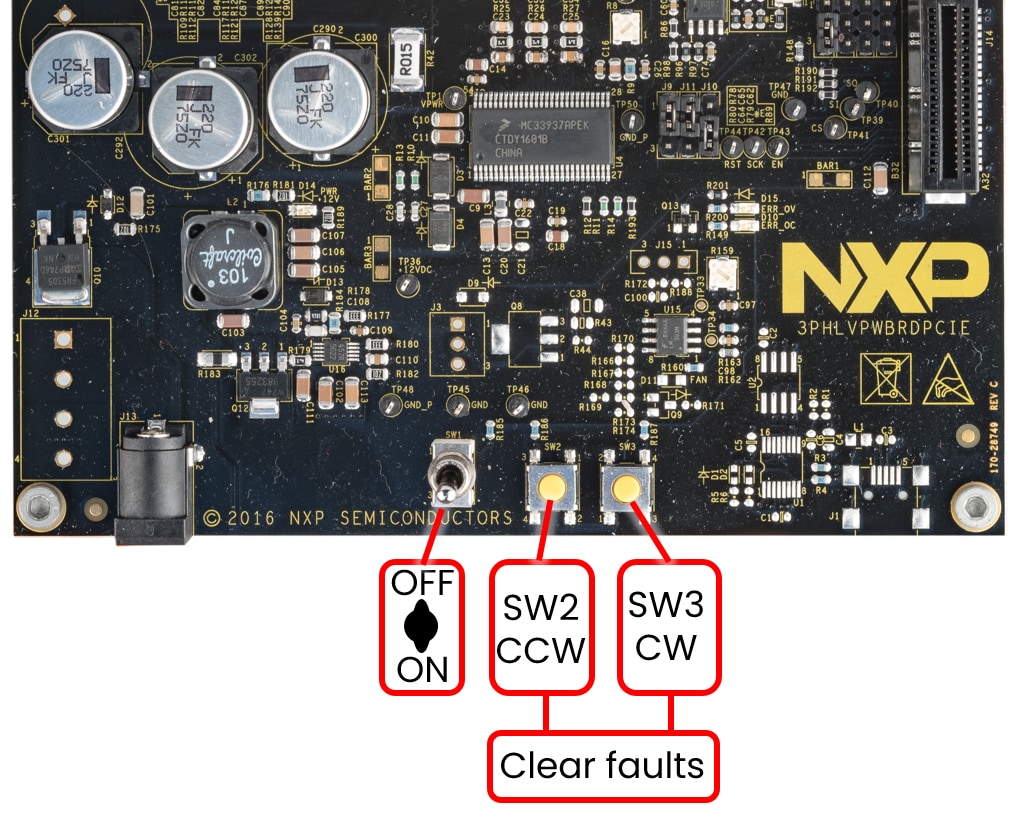

Optionally you may drive the motor speed by SW1 switch and SW3/SW2 push buttons on the power stage board.

- Move the SW1 bar down (out of board direction) to get application ON

- Press SW3/SW2 to initiate clockwise/counterclockwise spinning of the rotor

- Another SW3/SW2 pressing will increase/decrease the motor speed

- Move the SW1 bar up (to the center of board direction) to stop the motor

- Simultaneously pressing SW3 and SW2 will clear the pending faults

Design Resources

Board Information

Chip Documents

Application Documents

Software

-

MCSPTR2AK396 Development Kit Application Software

- Automotive Software Package Manager

- S32K3 Standard Software Package

- S32K3 Reference Software Package

- S32 Design Studio for S32 Platform

- Real-Time Drivers (RTD)

- Automotive Math and Motor Control Library (AMMCLib)

- FreeMASTER Run-Time Debugging Tool

- Motor Control Application Tuning (MCAT) Tool

- Model-Based Design Toolbox (MBDT)

Support

Training

Forums

Connect with other engineers and get expert advice on designing with the MCSPTR2AK396 on one of our community sites.

On this page

- 2.1

Get S32 Design Studio for S32 Platform IDE

- 2.2

Downloading the Real-Time Drivers (RTD)

- 2.3

Install the RTD drivers

- 2.4

Download eTPU SW

- 2.5

Install eTPU SW

- 2.6

Install FreeMASTER Communication Driver

- 2.7

Get FreeMASTER Application Tool

- 2.8

Get AMMCLib for S32K3

- 2.9

Get the MCSPTR2AK396 Motor Control Application Software