Technologists in just about every discipline look for ways to make things smaller, more durable, and, of course, more

secure. It’s the same in identification, where recent developments in packaging, printing, and laminating are

paving the way for ultra-thin yet ultra-secure electronic IDs.

With packaging, for example, the trend toward miniaturization is making it possible to put smart, secure technologies

in eID cards while leaving room for additional features that make the document even more durable and even better

protected.

Thinner is Better

NXP is the world leader in contactless secure microcontroller technology, and is the number-one supplier of smartcard

ICs for identification. We are a pioneer in the area of miniaturization, and have introduced several generations of

contactless chip modules, each thinner than the one before it. Now, with our latest contactless module, the MOB10,

we’re enabling eIDs that can be thinner, but also more durable and more secure.

The NXP path to thinner packaging

The MOB10 is an impressive 20% slimmer than its predecessor. It measures just 200 µm – roughly four times

as thick as the average human hair. The MOB10 is so thin, in fact, that it can even be placed in a sheet of paper.

This was one of the driving factors behind the MOB10’s introduction, because it enables a new generation of

ePassports, which move the IC from the booklet’s cover to its data page, for an even more secure solution.

A New Kind of eID

Beyond the data pages of ePassports, though, the ultra-thin MOB10 can be applied to a variety of plastics and becomes

an integral part of the design, so any kind of identification document can be both slimmer and more secure. The

ultra-thin profile makes it possible to accommodate new security features and still include the secure

microcontroller and its antenna, without adding bulk. That can benefit just about any type of electronic

identification document, from national eID cards and eHealth cards to citizenship cards, resident cards,

driver’s licenses, and even cards used for physical or logical access to secure areas.

Security layers

Today’s eIDs are a complex combination of closely interlinked elements. They build on a sophisticated mix of

visual effects, special printing technologies, secure lamination, and electronic personalization. Packing all those

things into a single, slim ID card takes a lot of innovation.

The exact mix of features used in a given eID will vary, depending on the application, but each feature takes up a

certain amount of space on the card and can add to the thickness of the document. In addition to the chip embedded

inside the card, a typical eID is equipped with features that can be readily seen with the naked eye, and can have

“hidden” features that can only be seen with a magnifier, a UV lamp, or other type of tool issued to

verifying authorities. The German eID card, for example, includes more than 20 different security features, in

addition to the secure contactless chip embedded inside.

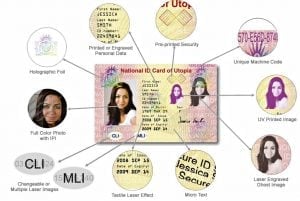

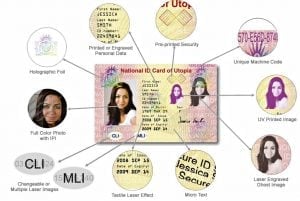

The illustration gives a sampling of the types of features now available for eIDs.

Security features added to the surface of an eID

- Changeable Laser Image (CLI) and Multiple Laser Image (MLI) – these are arrays of lenticular

lenses, measuring in microns, that are laser personalized, from different angles, with an image. On the final

card, the image presented will change depending on the viewing angle. If there is only one image, it’s a

CLI, if there’s more than one, it’s an MLI.

- Full color photo with Invisible Personal Information (IPI) – Personal data, such as a name or

number, is encoded in the portrait. This is a Class 2 feature, since the data can only be read with a dedicated

decoding lens.

- Holographic foil – A special type of foil that is printed in such a way that it appears to have

a three-dimensional image. A hologram effect can now be produced using nano technology and applied to any

material, including the data page of an ePassport.

- Printed or engraved personal data – This is the main portion of the eID, using machine readable

text to display key pieces of data.

- Pre-printed security — This printed item indicates the card blank came from an authorized

issuer, meaning the eID uses a genuine card base as its foundation.

- Unique machine code – A machine-verifiable code assigned to the eID, much like a serial number

for the document.

- UV printed image – The intricate background pattern, called a guilloche, luminesces in various

colors under UV light.

- Laser-engraved ghost image – A very fine matte area is applied to the glossy card surface and

printed with an image. Since the matte area reflects less light than the glossy area, the image appears under

reflection.

- Micro text – A font size of only a few microns is used to print data onto the security

background. The text is considered a Class 2 feature, since it can only be read with a magnifier.

- Tactile laser effect – Important pieces of information, like the expiration date or a six-digit

card access number, are laser-engraved in a raised format that can be felt with a finger.

Scalable Security

With an ultra-thin module like the MOB10, the eID can support a broader set of features, and still include the

circuitry that stores personal information, while retaining an acceptable profile. Taken as a whole, the security

features on the surface and embedded inside of eIDs make it even harder, if not impossible, to forge or hack

identity documents.

The secure microcontroller housed in the MOB10 adds a high level resistance to fraud, copying, and the alteration of

data on original documents. It can be programmed to support additional security features without adding steps to the

production process or the thickness of the document. The secure microcontroller becomes an integral part of the

design. It can evolve as security requirements change, yet continue to support easy document verification on

different inspection levels, with or without special tools.

Easier manufacturing

The MOB10 is the first ultra-thin platform designed to be compatible with existing production lines. This helps

manufacturers keep costs low, and makes it easier to transition from printing booklet covers to data pages.

The MOB10 is available in the MOA8 footprint, so it can be integrated into existing manufacturing processes without

modifying or replacing the in-place setup. Also, because the MOB10 module can accommodate a number of different

secure ICs, the designers of ePassports can support a range of ICs without increasing production costs or slowing

down the production line. Manufacturers often produce multiple eIDs on the same production line, so having a single

module support many formats helps streamline operations and minimize costs.

The MOB10 is designed for high volume and offers higher density per reel. This optimizes machine throughput and

storage space, so the producers of eIDs can operate more cost-efficiently while producing more resilient end

products. To ensure full flexibility for the implementation, the MOB10 solution is compatible with ICAO 9303 and

ISO/IEC 14443.

Paving the way

At NXP, our proven MOB modules set the industry standard by focusing on production, productivity, quality, and

security. With the MOB10, we can look forward a new generation of electronic IDs that are smarter, more convenient

to use, and, perhaps most important of all, ensure the highest levels of privacy and protection.