In

“IoT Sensing Software Development Kit,”

I introduced the new ISSDK component within the Kinetis SDK. I also mentioned

it included NXP Sensor Fusion for Kinetis MCUs Version 7.00. Today,

I’ll provide details.

NXP, and Freescale before it, have been providing an open source library for

development of sensor fusion applications for a couple of years now.

Version 4.22 started that trend. Version 5.00 followed a year later with

significant enhancements. Version 6.00 was never published. It added support

for precision accelerometer trim and storing of trim parameters into NVM. But

about that time, we learned that the CodeWarrior and Processor Expert tools

were being phased out for Kinetis MCUs. It was time to retool. That’s

where Version 7.00 comes into play. It is based on the V6.00 baseline,

but with a LOT of changes:

- The CodeWarrior software development tool support is retired

- Processor Expert software support is retired

- MQX RTOS support is retired

- FreeRTOS support has been added

-

Support for bare metal projects has been added. This also dramatically

reduces the amount of flash memory you need to store the application.

-

Because it is now part of the KEX ecosystem, you now get support for:

-

Kinetis Design Studio IDE v3.2

- IAR Embedded Workbench for Arm version 7.50.1

- MDK-ARM Microcontroller Development Kit (Keil)® 5.17

-

Makefiles support with GCC revision 4.9-2015-q3-update from Arm Embedded

- Atollic® TrueSTUDIO® 5.4.0

- Precision trim for accelerometers

-

Storage of all sensor trim values to non-volatile flash

memory (via the updated Sensor Fusion Toolbox for Windows)

-

Ability to power down selected sensors (specifically the gyro) during

periods of inactivity

-

Top-level functions have been re-partitioned to make it obscenely easy to

integrate sensor fusion capabilities into your code

-

Hardware facing functions have been streamlined for easy portability to

non-Kinetis platforms.

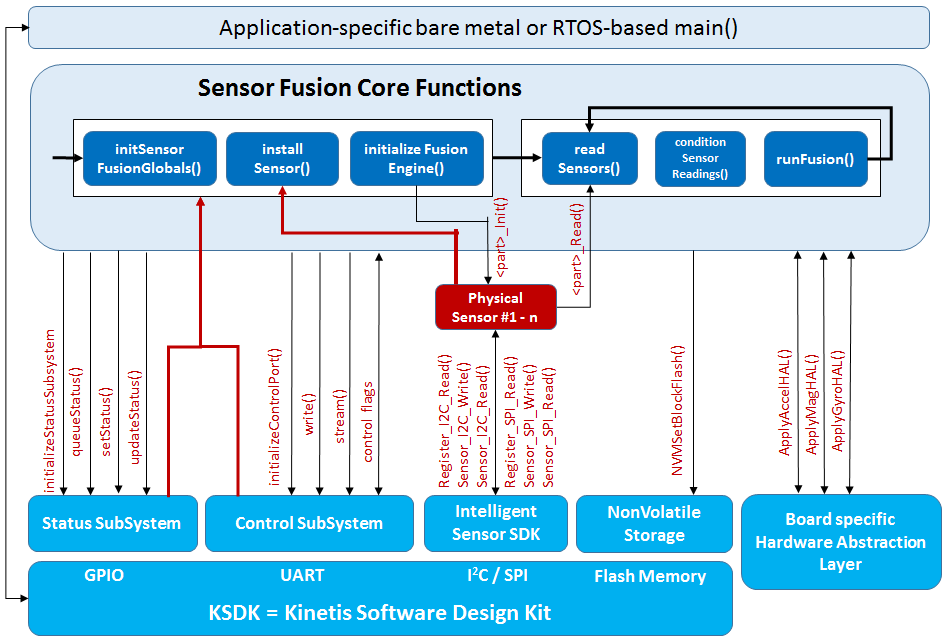

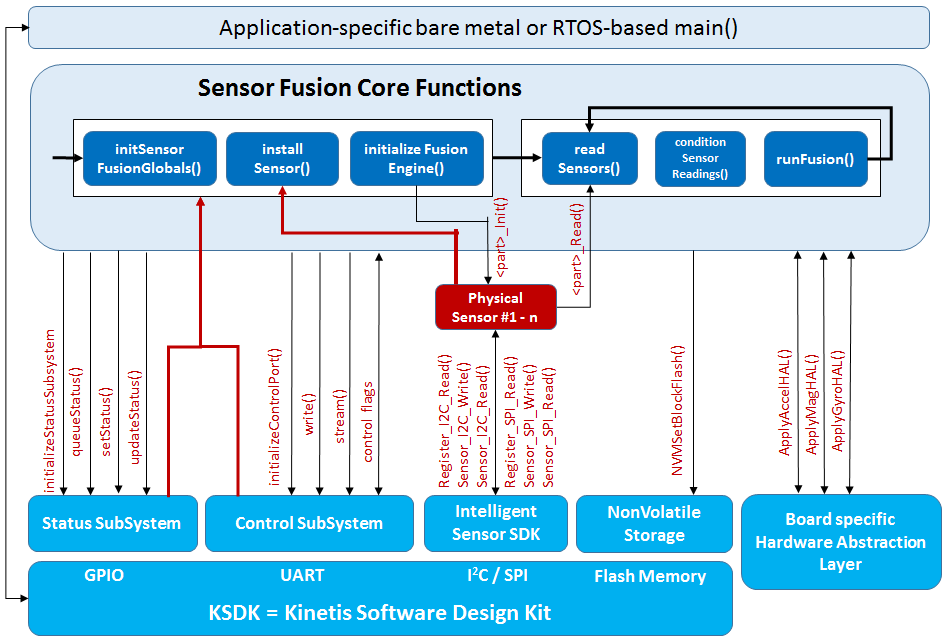

The block diagram below shows how the sensor fusion library fits into your

application. The number of top level functions you need to remember is

extremely modest. Sensor drivers are already provided for NXP sensors,

but it’s also easy to write your own if you want to enable some other

device.

In this solution, we will use the

FXOS8700 6-axis magnetometer and accelerometer,

FXAS21002 3-axis gyroscope and the

MPL3115 barometric pressure sensors. Let’s take a look at a bare metal main(). The

first code block pulls in headers specific to your hardware:

// KSDK and ISSDK Headers

#include "fsl_debug_console.h" // KSDK header file for the debug interface

#include "board.h" // KSDK header file to define board configuration

#include "pin_mux.h" // KSDK header file for pin mux initialization functions

#include "clock_config.h" // KSDK header file for clock configuration

#include "fsl_port.h" // KSDK header file for Port I/O control

#include "fsl_i2c.h" // KSDK header file for I2C interfaces

#include "fsl_pit.h" // KSDK header file for Periodic Interval Timer

#include "Driver_I2C.h" // CMSIS I2C Driver

#include "Driver_I2C_SDK2.h" // ISSDK CMSIS I2C Driver

#include "fxas21002.h" // Gyroscope register and bit-field definitions

#include "mpl3115.h" // Pressure sensor register and bit-field definitions

#include "fxos8700.h" // 6-axis accel/mag register and bit-field definitions

#include "fsl_smc.h"

Next we include a number of sensor fusion headers:

#include "sensor_fusion.h" // Top-level magCal and sensor fusion interfaces

#include "control.h" // Command/Streaming interface - application-specific

#include "status.h" // Status indicator interface - application-specific

#include "drivers.h" // NXP sensor drivers OR customer-supplied drivers

#include "driver_pit.h" // PIT is used to control main() timing loop

You will need to define a number of global data structures:

SensorFusionGlobals sfg; ///< This is the primary sensor fusion data structure

ControlSubsystem controlSubsystem; ///< Used for serial communications

StatusSubsystem statusSubsystem; ///< Provides visual (usually LED) status indicator

PhysicalSensor sensors[3]; ///< This implementation uses up to 3 sensors

Now let’s take a look at main(). Start by doing some general hardware

configuration:

int main(void) // This is a bare-metal implementation of the NXP sensor fusion demo build.

{

uint16_t i=0; // general counter variable

BOARD_InitPins(); // defined in pin_mux.c, initializes pkg pins

BOARD_BootClockRUN(); // defined in clock_config.c, initializes clocks

BOARD_InitDebugConsole(); // defined in board.c, initializes the OpenSDA port

Next, initialize the I2C-bus used for sensor communications:

ARM_DRIVER_I2C* I2Cdrv = &I2C_S_DRIVER_BLOCKING; // Defined by ISSDK

I2Cdrv->Initialize(NULL); // Initialize the I2C KSDK driver

I2Cdrv->Control(ARM_I2C_BUS_SPEED, ARM_I2C_BUS_SPEED_FAST); // Configure the I2C-bus speed

Now initialize various subsystems associated with sensor fusion:

initializeControlPort(&controlSubsystem); // configure pins and ports for the control sub-system

initializeStatusSubsystem(&statusSubsystem); // configure pins and ports for the status sub-system

// Initialize sensor fusion structures

initSensorFusionGlobals(&sfg, &statusSubsystem, &controlSubsystem);

Sensors are installed at runtime:

sfg.installSensor(&sfg, &sensors[0], FXOS8700_I2C_ADDR, 1, (void*) I2Cdrv, FXOS8700_Init, FXOS8700_Read);

sfg.installSensor(&sfg, &sensors[1], FXAS21002_I2C_ADDR, 1, (void*) I2Cdrv, FXAS21002_Init, FXAS21002_Read);

sfg.installSensor(&sfg, &sensors[2], MPL3115_I2C_ADDR, 1, (void*) I2Cdrv, MPL3115_Init, MPL3115_Read);

Start up the fusion engine, hardware timer and initial status:

sfg.initializeFusionEngine(&sfg); // This will initialize sensors and magnetic calibration

pit_init(1000000/FUSION_HZ); // pitIsrFlag will be set true at FUSION_HZ periodic intervals

sfg.setStatus(&sfg, NORMAL); // If we got this far, let's set status state to NORMAL

Now we have our main loop, which is timed via a periodic interval timer:

while (true)

{

if (true == pitIsrFlag) { // Check whether occur interupt and toggle LED

sfg.readSensors(&sfg, 1); // Reads sensors, applies HAL and does averaging

sfg.conditionSensorReadings(&sfg); // MagCal is run as part of this

sfg.runFusion(&sfg); // Run the actual fusion algorithms

sfg.loopcounter++; // Used to "serialize" mag cal operations

i=i+1;

if (i>=4) { // Some status codes include a "blink" feature. This loop

i=0; // should cycle at least 4X for that to operate correctly.

sfg.updateStatus(&sfg); // This is where pending status updates are made visible

}

sfg.queueStatus(&sfg, NORMAL); // assume NORMAL status for next pass through the loop

// Send stream data to the Sensor Fusion Toolbox

sfg.pControlSubsystem->stream(&sfg, sUARTOutputBuffer);

pitIsrFlag = false; // Reset the flag for the next cycle

}

}

}

Even though we’ve used standard C, we’ve used an objected

oriented coding style for the top-level interface. Functions that

operate on a structure are actually installed as part of that structure, just

as in C++. Status and control subsystems are installed at runtime. This allows you to install your own versions rather than use the

NXP defaults. Sensors to be used by the application are also explicitly

installed. Then we simply start the fusion subsystem and a system timer

and drop into a main loop.

I think you will agree that this release makes it easier to see and comprehend

the overall application structure than it was with previous libraries. To find

more information, go to

NXP® Sensor Fusion

and

MCUXpresso SDK Builder

to download this release and

nxp.com/FRDM to order development boards.

Our next posting in the series will look at sensor drivers and a FreeRTOS

implementation of the same application shown in bare metal form above.

Michael Stanley “works” on fun sensors and systems

topics.