There have been several points, in the history of manufacturing, when technology has truly revolutionized the way

products are made. In the early part of the 20th century, the steam engine and electrification led to

mass production and in the 1970s, when robotics, computers and other types of automation came on the scene,

productivity got another big boost. Since then, though, technology has had more of an incremental effect on

manufacturing, especially when you think about what’s happened over the same period in other areas, such as

information technology, mobile communications and e-commerce.

But that’s changing. The manufacturing sector has become increasingly digital, using connected systems to

control complex, collaborative processes. Machines and products now communicate with each other, so as to

cooperatively drive production. In this new way of working, a product can find its way through the production

process independently, minimizing the need for human intervention and reducing the chance of human error. The

result is heightened productivity, with the ability to respond to changes faster than ever before, and the ability

to customize on a grand scale – all while reducing unit costs and saving energy.

This trend of digitization is more than an evolution, in terms of productivity, safety, and cost and can

legitimately be called a revolution. Analysts have, in fact, started calling this the fourth industrial revolution or Industry 4.0. The term refers to the use of a wide range of technologies, from semiconductor products like

sensors and microcontrollers, to things like autonomous robots and simulators, big data and analytics and, of

course, cloud computing and the Internet of Things.

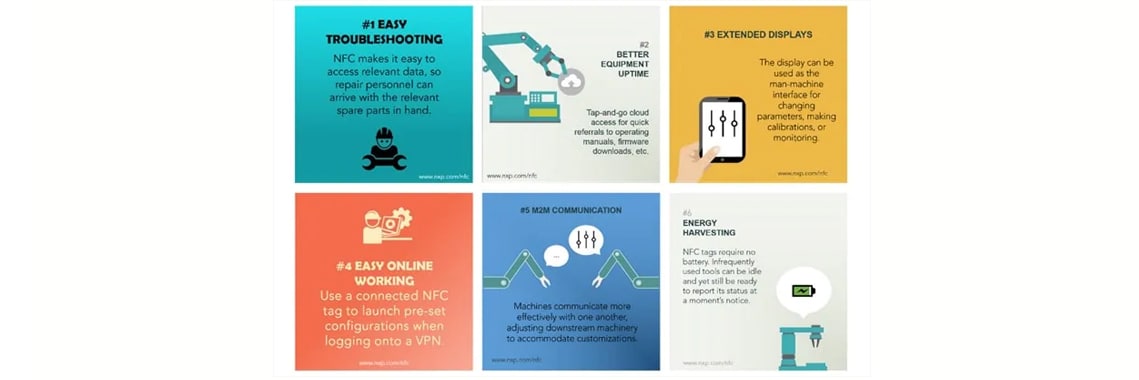

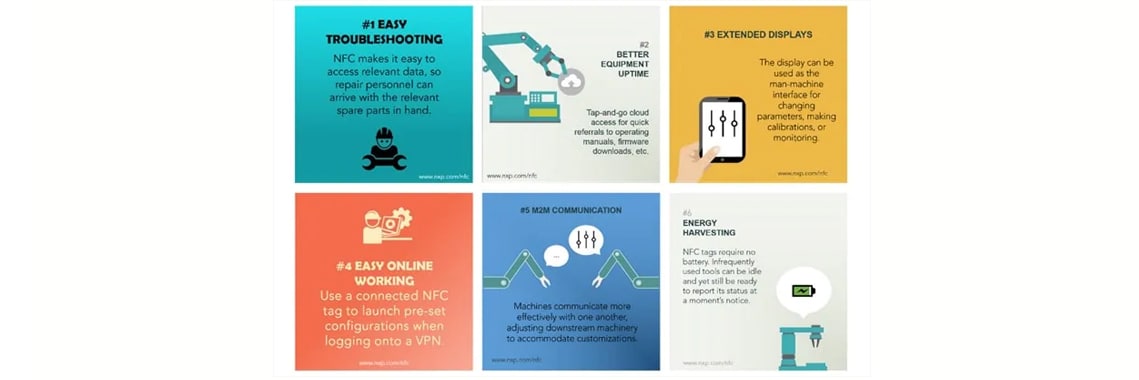

One of the newest additions to the mix is Near Field Communication, or NFC, which adds new levels of

convenience, communication and configurability throughout the manufacturing process. Take a look.

Our graphics show just some of the ways that NFC can enhance manufacturing, and there are sure to be even more

applications as developers begin to explore the possibilities. Follow us on Facebook or Twitter to discover more ways how NXP

technology can enable Industry 4.0 and join the discussion: What role do you think NFC will play in this latest

industrial revolution? Which further use cases can you foresee for NFC in the industrial environment? And what might

Industry 5.0 look like?

Learn more

To get the details about NFC on manufacturing floors, download our new white paper, titled “What NFC means for smart factories, intelligent

supply chains and Industry 4.0”.