PLCs are an essential part of any production line and as we move deeper into

the fourth industrial revolution, more internet-connected sensors and systems

are interfacing with PLCs. This exposes the complete system to cyber-attacks

that are difficult to predict and can lead to complete system failure, life

endangerment and financial loss. To mitigate this, designers should take

preventative measures at both the hardware and software level to protect PLCs

and other connected devices in the factory.

Common Security Attacks

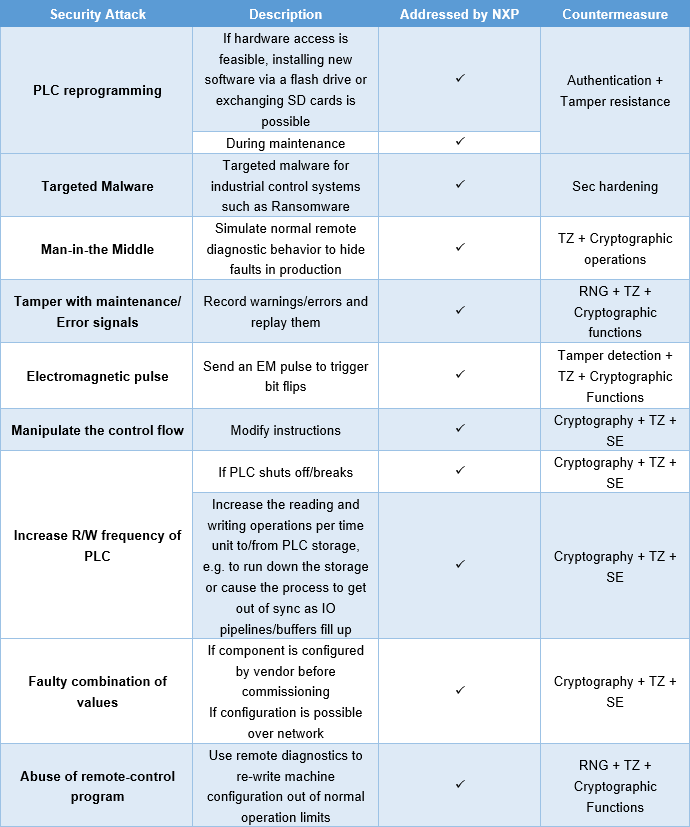

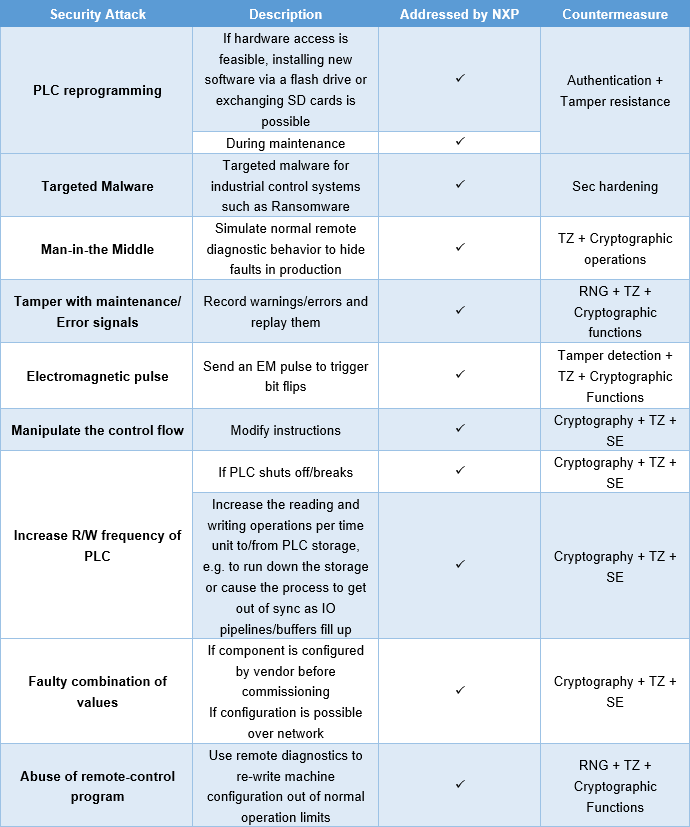

Table 1. shows common security attacks on a PLC system including local attacks

such as PLC reprogramming via a flash drive or SD card and remote attacks such

as man-in-the-middle that hide potential faults in production. For example, in

a food and beverage manufacturing facility producing ingredients for chocolate

or baking, it is essential to track all chemicals in a mixture and monitor key

events such as a faulty boiler. A man-in-the-middle attack that hides

potential faults can result in erroneous mixtures unbeknownst to the operator.

Table 1. Micro Safety PLC Security Attacks

PLC Design with Security Features

NXP has developed a broad portfolio of scalable security solutions that

provide a foundation for achieving the most effective security levels based on

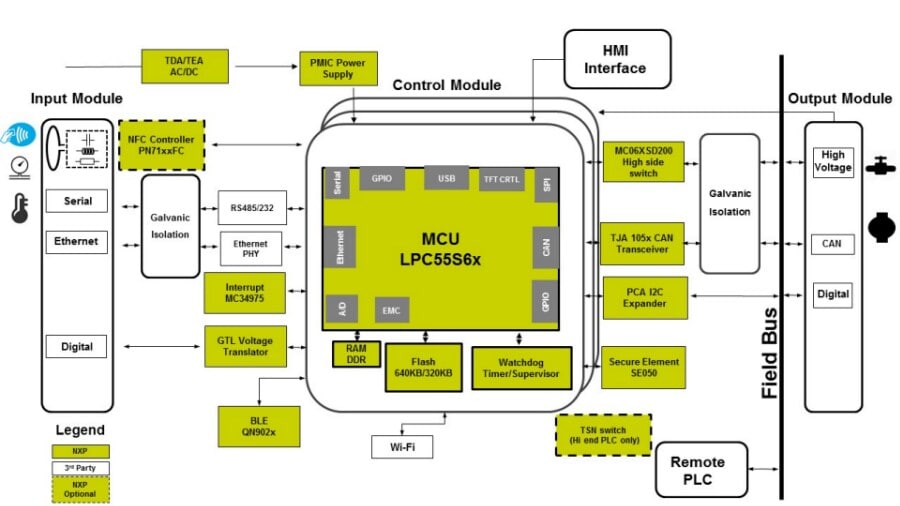

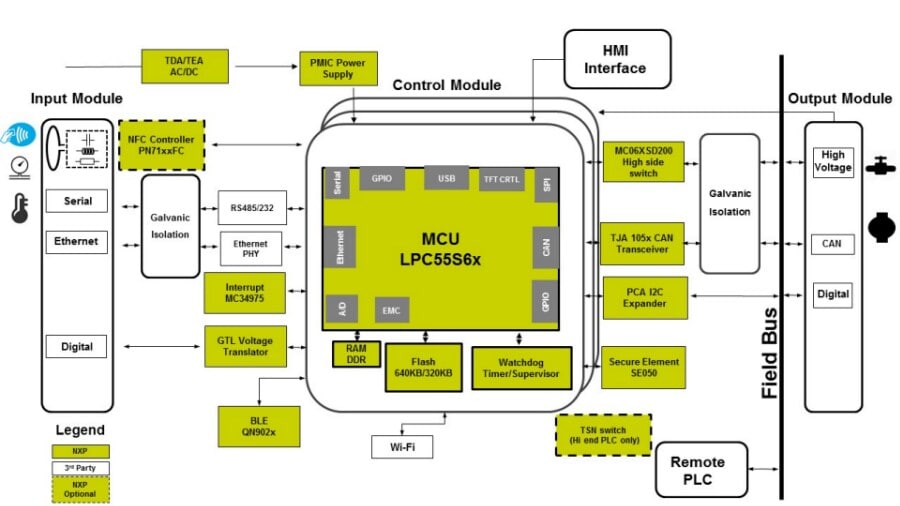

the potential security attacks on a system. Figure 1. shows a Micro Safety PLC

solution that addresses the attacks shown in Table 1.

Figure 1. Micro Safety PLC Block Diagram

The LPC55S6x MCU incorporates software-based security based on Arm TrustZone

(TZ), which enables a secure and isolated execution environment that handles

trusted operations including communication to external memory and software

updates. To further isolate protected operations, the SE050 secure element

provides support of main TPM functionalities including physical isolation that

protects keys, tamper resistant protection and software authentication.

It also creates a secure channel for data transfer to the MCU.

The combination of the LPC55S6x MCU and SE050 secure element provide a

countermeasure to maximize security and maintain system integrity throughout

the lifecycle of the PLC. This minimizes system downtime and critical

information leakage that promotes safety and quality.

Additional steps can be taken to mitigate security attacks such as regular

updates to antivirus software to reduce malware injection instances,

appropriately managed access level to PLCs by personnel and only allowing

certain PCs to be used for programming.

Additional Resources

Click here to learn more about NXP factory automation solutions

Learn more about NXP security solutions

Stuck on something? Get answers to your questions on our community page