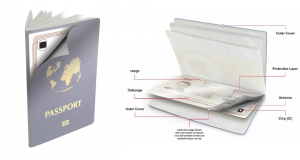

In today’s electronic passports, the contactless smart card IC used to

store personal information about the traveler is usually embedded in the

stiff, multi-layer cardboard used for the booklet’s cover. Having the

IC in the cover has proven itself to be an effective approach, given the

enormous number of secure border crossings that cover-mounted ICs have made

possible, but moving the IC to the inside of the ePassport, to the data page,

would be an even more secure approach.

Forensic crime experts have expressed concern over having the chip in the

cover, since criminals could, in theory, swap a fake cover for a real one or

insert counterfeit pages into a genuine cover. Placing the chip inside the

data page would create a stronger link between the passport holder and the

printed information, and would give the electronically stored information an

extra level of protection against physical attacks.

Why hasn’t the smart card IC already moved to the data page? Because,

until now, the module that houses the IC has been too thick to work with a

data page.

Moving ID circuitry from the cover to the inside pages increases

security

Now it’s possible

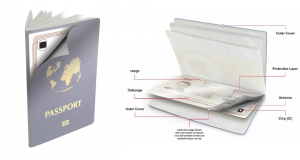

The goal of being able to place an IC in the data page of an ePassport has

been one of the reasons why our ID engineers focus on miniaturization. And

now, with our latest contactless module, the MOB10, the data page is within

reach. Measuring just 200 µm – roughly four times the thickness of

the average human hair, the MOB10 is an impressive 20% thinner than its

predecessor, and ideally suited for use in ePassport data pages.

The NXP path to thinner packaging

The MOB10 is amazingly thin, but it’s also designed to withstand the

mechanical stresses of ID production and in-field use. The module can sustain

the micro-cracks associated with naked flip-chips, and can hold up in the face

of environmental stresses, such as exposure to humidity, chemicals and

solvents. Increased product quality also makes the MOB10 less susceptible to

thermal stress and reverse engineering tactics, including light and laser

attacks. What’s more, the antenna pads of the MOB10 are still large

enough, despite the smaller footprint, to support efficient connection

technologies, so there’s no loss of reliability.

All this combines to create a smart card IC that is thin enough, durable

enough and secure enough to be embedded in the data page. The IC can become

part of the page itself, which means any attempt to peel off the IC or

re-insert it would destroy the page and make the entire passport unusable.

Having an ultra-thin yet durable module also means that the data page can be

made out of something stronger than paper, like polycarbonate. Using

polycarbonate creates a more resilient data page, able to withstand all the

rigors of real-world use for at least a decade or more and also opens up

possibilities for adding extra security layers.

Room for extra security layers

With polycarbonate as the basis for the data page, ePassport manufacturers can

take advantage of new production techniques that make eIDs even more secure.

The German eID card, for example, is embedded with a secure contactless chip,

but also uses layers of polycarbonate to include more than 20 different

security features. Some of these security features, such as images that change

depending on the viewing angle, can be seen with the naked eye, while other

features, such as UV printing and micro text, can only be viewed with special

equipment.

Packing all those layers into a single, standard-sized eID card takes a lot of

innovation and requires a sophisticated mix of visual effects, special

printing technologies, secure lamination and electronic personalization. Now,

with an ultra-thin module like the MOB10 embedded in the data page, ePassports

can begin taking advantage of these advanced, polycarbonate-based security

features and still include the secure microcontroller and its antenna,

without adding bulk.

The secure microcontroller housed in the MOB10 can be programmed to support

additional security features without adding steps to the production process or

the thickness of the data page. The secure microcontroller becomes an integral

part of the data page and can evolve as security requirements change, yet

continue to support easy document verification on different inspection levels,

with or without special tools.

Easier manufacturing

The MOB10 is the first ultra-thin platform designed to be compatible with

existing production lines. This helps manufacturers keep costs low, and makes

it easier to evolve production capacity as requirements change.

The MOB10 is available in the MOA8 footprint, so it can be integrated into

existing manufacturing processes without modifying or replacing the in-place

setup. Also, because the MOB10 module can accommodate a number of different

secure ICs, the designers of ePassports can support a range of ICs without

increasing production costs or slowing down the production line. Manufacturers

often produce eIDs and ePassports on the same production line, so having a

single module support multiple formats helps streamline operations and

minimize costs.

The MOB10 is designed for high volume, and offers higher density per reel.

This optimizes machine throughput and storage space, so the producers of

ePassports can operate more cost-efficiently while producing more resilient

end products. To ensure full flexibility for the implementation, the MOB10

solution is compatible with ICAO 9303 and ISO/IEC 14443.

Paving the way

For nearly a decade, our proven MOB modules have set the industry standard by

focusing on production, productivity, quality and security. With the MOB10,

we can look forward to lighter, more durable and more secure ePassports, with

smart card ICs embedded in their data pages instead of their booklet covers.

What’s more, the MOB10 will have an impact beyond ePassports, since the

ultra-thin format can be used to boost security in other types of eIDs, too.

The result will be smarter, more convenient ways for us to identify ourselves,

while ensuring the highest levels of privacy and protection.

NXP Webinar

To learn more about the MOB10, NXP will host a webinar on Wednesday, November

8 between 12-8 a.m. PST.

To register for the free webinar, click here.