Green and next-generation mobility is turning out to be a key factor in the automotive industry

bounce back after Covid-19. With record Electric Vehicle sales forecast for 2021, governments and

investor interest in forward-looking mobility technologies have opened the door to funding and

incentives to continue sweetening the move to electric.

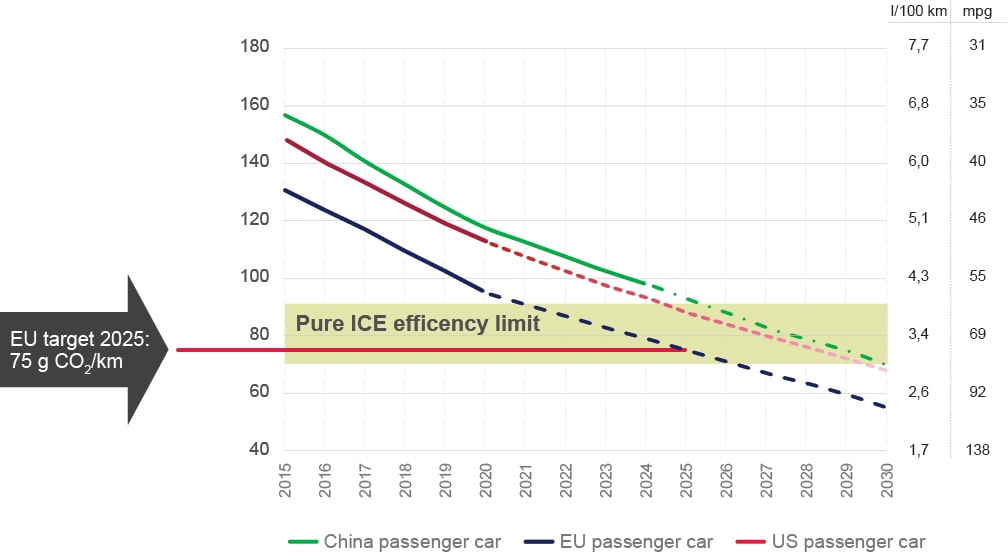

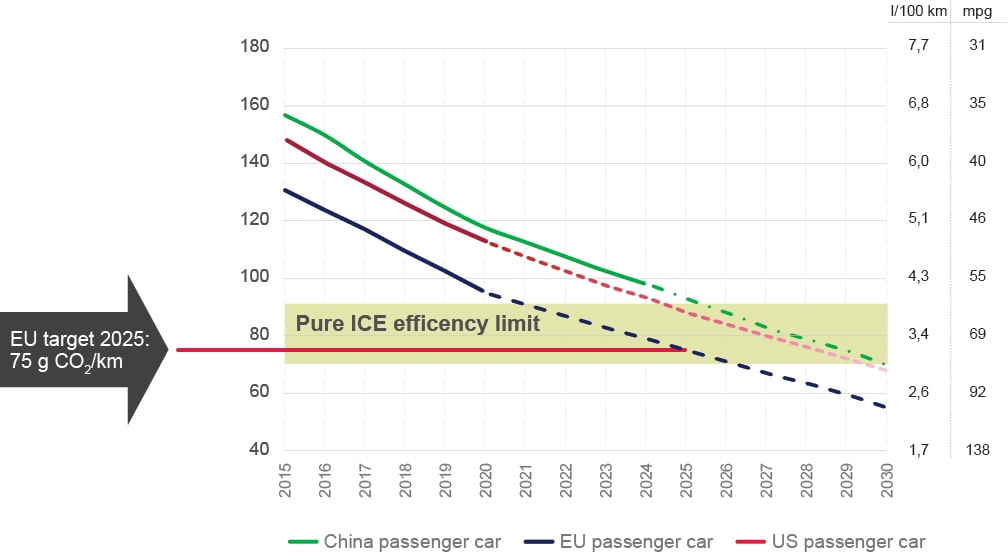

The transport sector, responsible for around 24% of CO2 emissions globally, is fully in the

environmental spotlight, and governments are pushing ahead with ever stricter regulations on

vehicle emissions. Norway is at the more aggressive end of the scale, planning to phase out all

new sales of internal combustion engine, (ICE), passenger cars by 2025. In the rest of Europe,

targets vary between 2030 and 2040, and China is aiming for a minimum 50% market share of New

energy vehicles (NEVs) by 2035.

The global automotive sector is responding to these looming emissions deadlines, with all major

manufacturers, including Volvo, Daimler, Volkswagen and Ford announcing massive investments in EV

development programs. Led by Tesla, the market leader with almost 30% of global sales in the first

half of 2020, global automakers collectively launched 143 new EVs in 2019 and plan to introduce

another 450 models by 2022.

Perhaps one of the biggest barriers to EV adoption thus far has been consumer perception over EV

price and performance limitations, especially range; the distance a vehicle can travel before the

battery needs to be recharged. These perceptions are progressively eroded as charging

infrastructure increases and the industry invests heavily in improving EV development, with a

strong focus on battery technology and efficiency improvement.

The modern automobile contains a number of advanced electronic subsystems, each responsible for

controlling specific functionality, such as ADAS, infotainment, functional safety and drivetrain,

including battery management. The architecture of these onboard systems has evolved away from

multiple electronic control units (ECUs) to a collection of domains, each managed by domain

controllers which share data and collaborate with each other. These domain controllers are based

on powerful, embedded microcontrollers which enable complex processing, using advanced techniques

such as virtualization, formerly the preserve of datacentre-based servers.

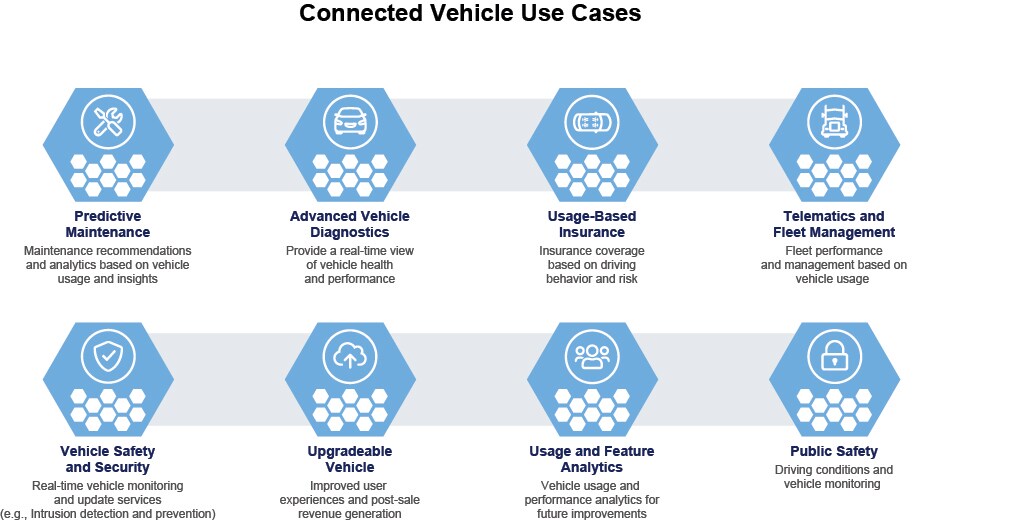

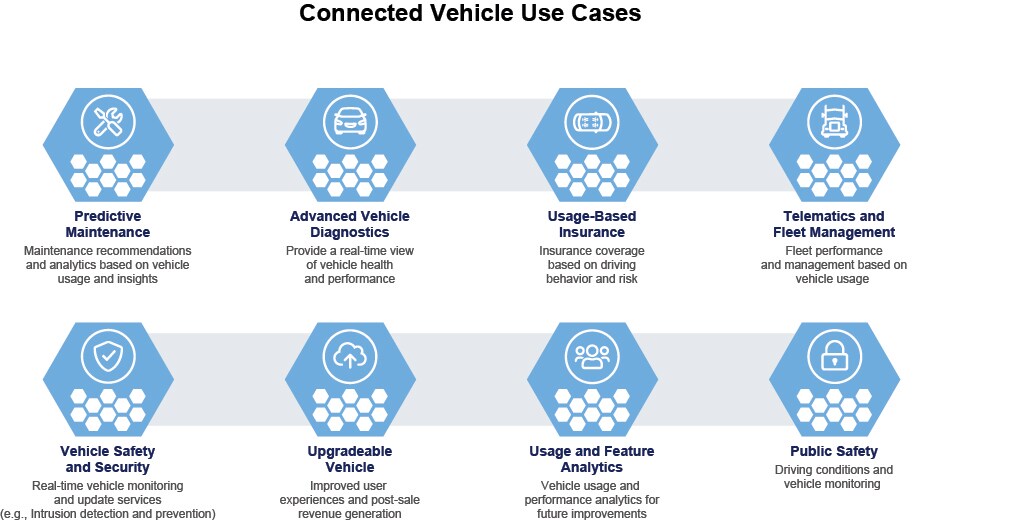

The impact of this onboard processing capability increases exponentially thanks to developments in

vehicle connectivity. C-V2X technology leverages the improved performance and coverage of cellular

networks to share the massive amounts of data generated by the car and its sensors, (up to 4

Terabytes per hour), to the cloud. This shared data enables a number of value-adding use cases,

including insurance, fleet management, preventative diagnostics and intrusion detection. The

connected car also brings the power of cloud-edge processing and artificial intelligence to

enhance the power of the onboard domain controllers.

The ongoing quest to improve vehicle efficiency and range is driving significant research and

development in the propulsion control domain, where energy optimization is a key challenge. A

hybrid-electric vehicle (HEV) can optionally be powered by its ICE or its electric motor, and the

vehicle’s range is directly dependent on the optimal use of these energy sources. Powerful control

algorithms within the propulsion controller decide which source to use, where to use the ICE,

where to use the electric motor and where regenerative braking can be used to increase the battery

charge state. The quality of these decisions, which directly affect the vehicles range, is

enhanced when the controller has access to cloud-based contextual information such as precise

location, traffic conditions, average speed of route, expected duration of journey, charging

stations locations, gradients on the planned route and driver style.

Vehicle connectivity also enables energy optimization to be enhanced by cloud-edge processing

techniques, where deep learning frameworks train machine learning (ML) models in the cloud. These

ML models are deployed to the domain controller in the vehicle (the edge) where they use a process

known as inferencing to make predictions based on real-time data generated from the vehicle’s

sensors.

To integrate the power of this technology, vehicle manufacturers require access to specialist

knowledge backed by in-depth resources and NXP Semiconductors are one of a select number of

organizations in the ecosystem with this capability. A global leader in auto microprocessors,

ADAS, radar, secure car access, infotainment and in-vehicle networking, the NXP comprehensive

solution portfolio enables our customers to accelerate the design of their next generation

automotive designs, enabling rapid time to market and scalability.

We have a strong track record working with some of the world’s largest vehicle manufacturers to

deliver high performance, safe and reliable mobile solutions. To learn more about our specific

capabilities, read our whitepaper “

Using Vehicle to Cloud Connectivity to Extend Electric Vehicle Range” on our website.