At the end of my

previous post – Top Clip

, I mentioned we would be moving on to the subject of top-side cooling next.

While we are definitely going there, I’d like to cover one other topic

first, which will ultimately form part of the overall top-side cooling story.

A question regularly asked by our customers is “Can I determine the

junction temperature (Tj) of my MOSFET from its case temperature

(Tcase)?”. This is a perfectly reasonable thing to ask

because we certainly want to know whether our MOSFETs are running at a safe

temperature in-circuit, but at the same time determining Tj

in-circuit can be extremely difficult. On the other hand, Tcase can

often be determined quite easily by using a thermocouple or (preferably) a

thermal camera. So, can we infer Tj from Tcase? This

question has arisen so often that we recently performed a series of

experiments to determine if such a correlation between Tj and Tcase

does indeed exist.

To carry out this experiment we need a method of applying a constant, known

power dissipation (PD) to a device whilst simultaneously monitoring

its steady-state Tj. Fortunately such a method exists and is

thoroughly documented in

JEDEC

standard JESD51-1. This describes how a MOSFET body diode can be used

simultaneously as both a heating element and calibrated temperature sensor.

JESD51-2 describes a standardized test environment so we can use that too, and

off-the-shelf test equipment for carrying out thermal analysis is available

from various manufacturers including

Analysis Tech

and

Mentor Graphics.

Most of the queries we received on this subject relate to

LFPAK56

devices, so we’ll focus on those in this experiment, and we’ll

carry out the tests for three different PCB copper areas and a range of power

dissipations. Add a thermal camera to measure Tcase on the top of

the device and we’re ready to go!

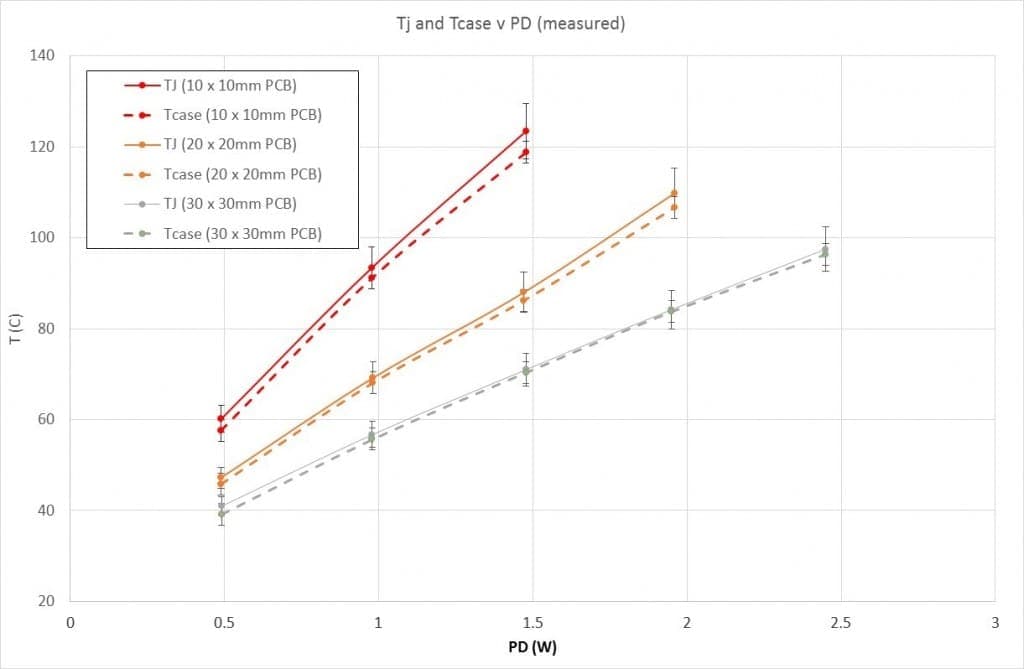

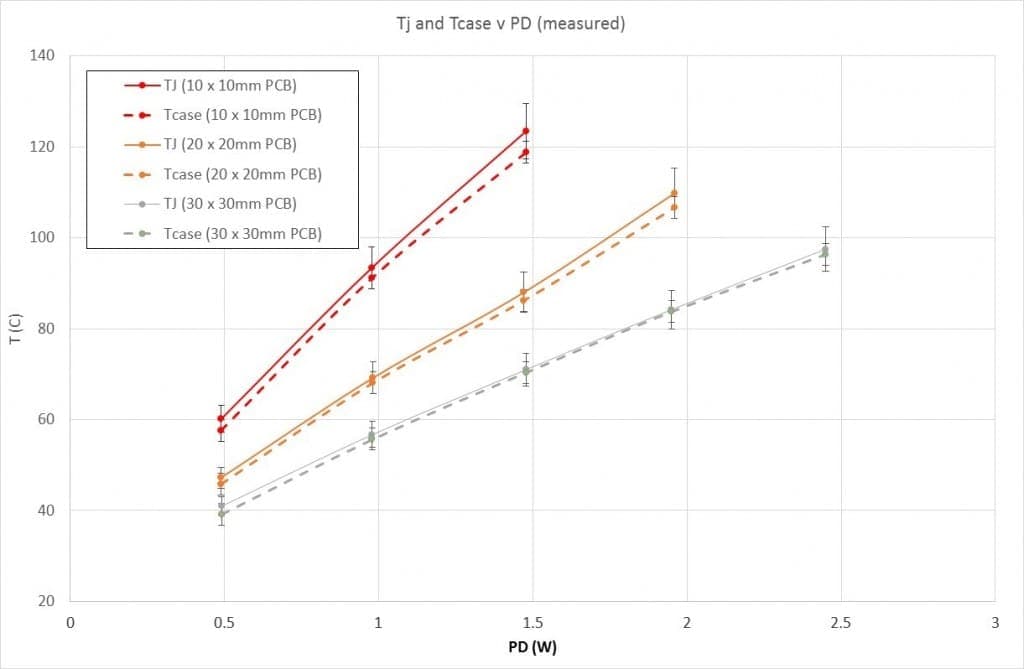

In the graph below you can see the results.

Figure 1 Measured Tj and Tcase v PD for an

LFPAK56 device on various PCBs

The graph of Figure 1 demonstrates that Tj and Tcase are

indeed very close in most cases – with the worst-case difference

being around 4% for the 10×10 mm PCB. Of course, as these are real

measurements we also have to consider that the measurement methods will have

their own accuracy limits, and these are included in the graph as vertical

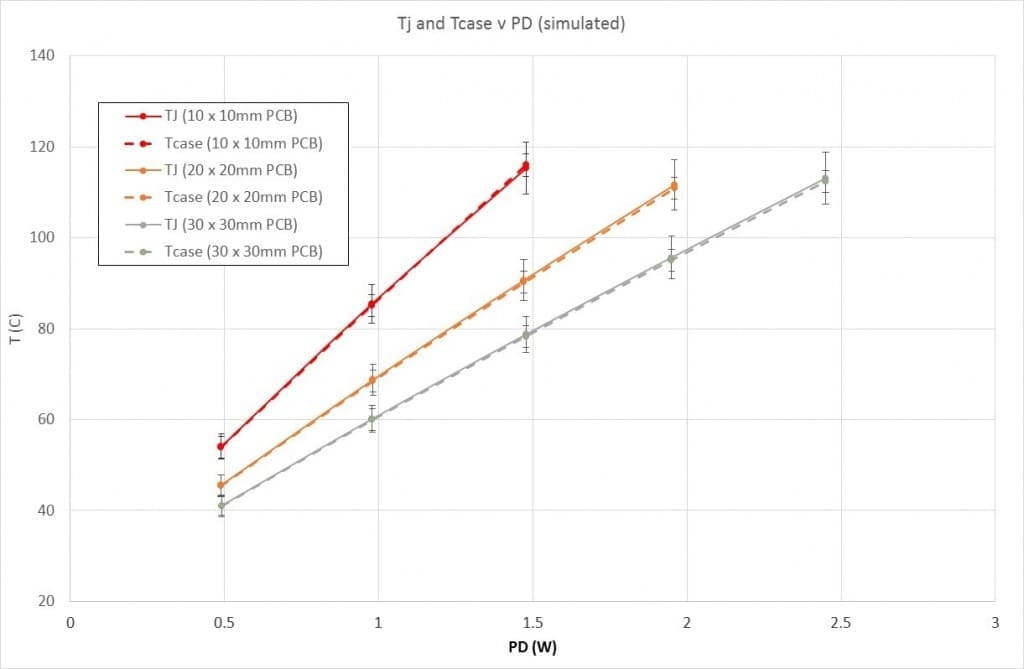

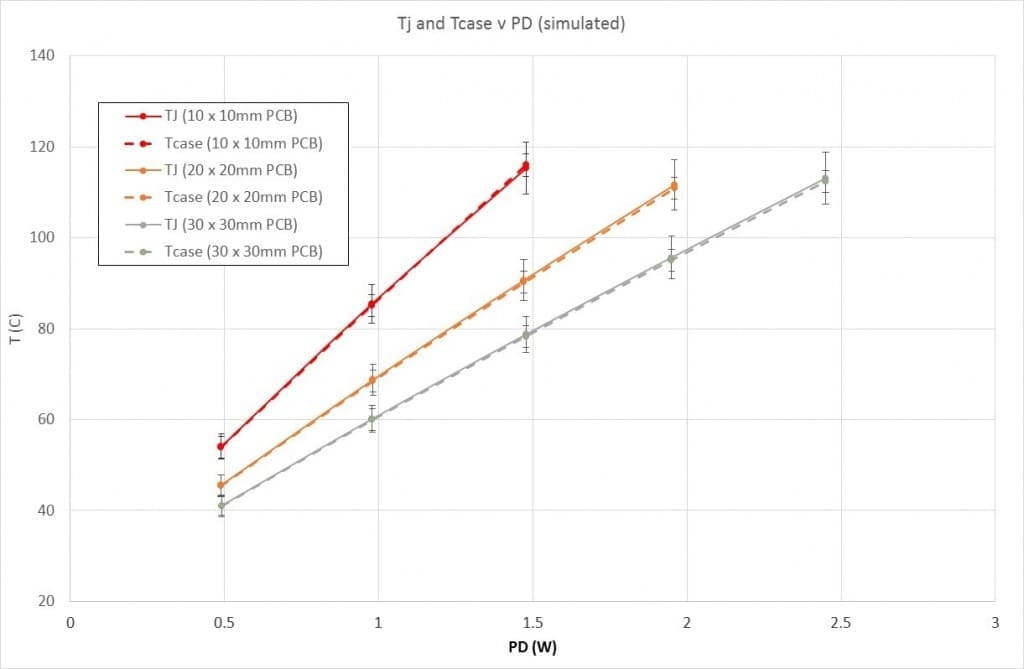

error bars. If I carry out thermal simulations of similar device and PCB

setups then the Tj and Tcase results are even closer, as

can be seen in Figure 2. This time, the temperatures are almost identical.

Figure 2 Simulated Tj and Tcase v PD for an LFPAK56 device on various

PCBs

This is a very useful result as it would tend to suggest that, for the LFPAK56

package at least, we can consider Tj and Tcase to be

almost the same with a reasonable degree of accuracy. It’s also

probably fair to say that this is another example of a non-intuitive result!

In my next post I’ll return to this subject and consider

why Tj and Tcase are so similar. In the

meantime, the interested reader might like to ponder for themselves reasons

why Tj @ Tcase (hint: and it doesn’t really have

anything to do with thermal resistances).