The MCX E series is the industry’s broadest portfolio of 5V microcontroller units (MCUs), bringing scalable performance, built-in functional safety and long-life reliability to industrial and appliance designs.

The expectations for modern industrial and appliance systems are higher than ever. Motors should run flawlessly for years, power conversion systems must endure harsh operating conditions, while every device needs protection against cyber threats and physical failures. Plainly, achieving this balance of performance and safety is far from simple.

The new MCX E31 family of microcontrollers changes that equation. This portfolio of 5V MCUs, blends built-in hardware safety measures, advanced security and extended reliability to help engineers slash time to certification without compromising performance and reliability.

Why Choose MCX E31?

Teams face a gamut of recurring pain points when building safety-critical or industrial systems. Certification consumes months of engineering effort, and system reliability is difficult to prove across extreme operating ranges. In this case, that many designs still require multiple MCUs to achieve both performance and functional safety.

Start developing today with the MCX E Series using the FRDM Development Platform. Explore our FRDM board portfolio.

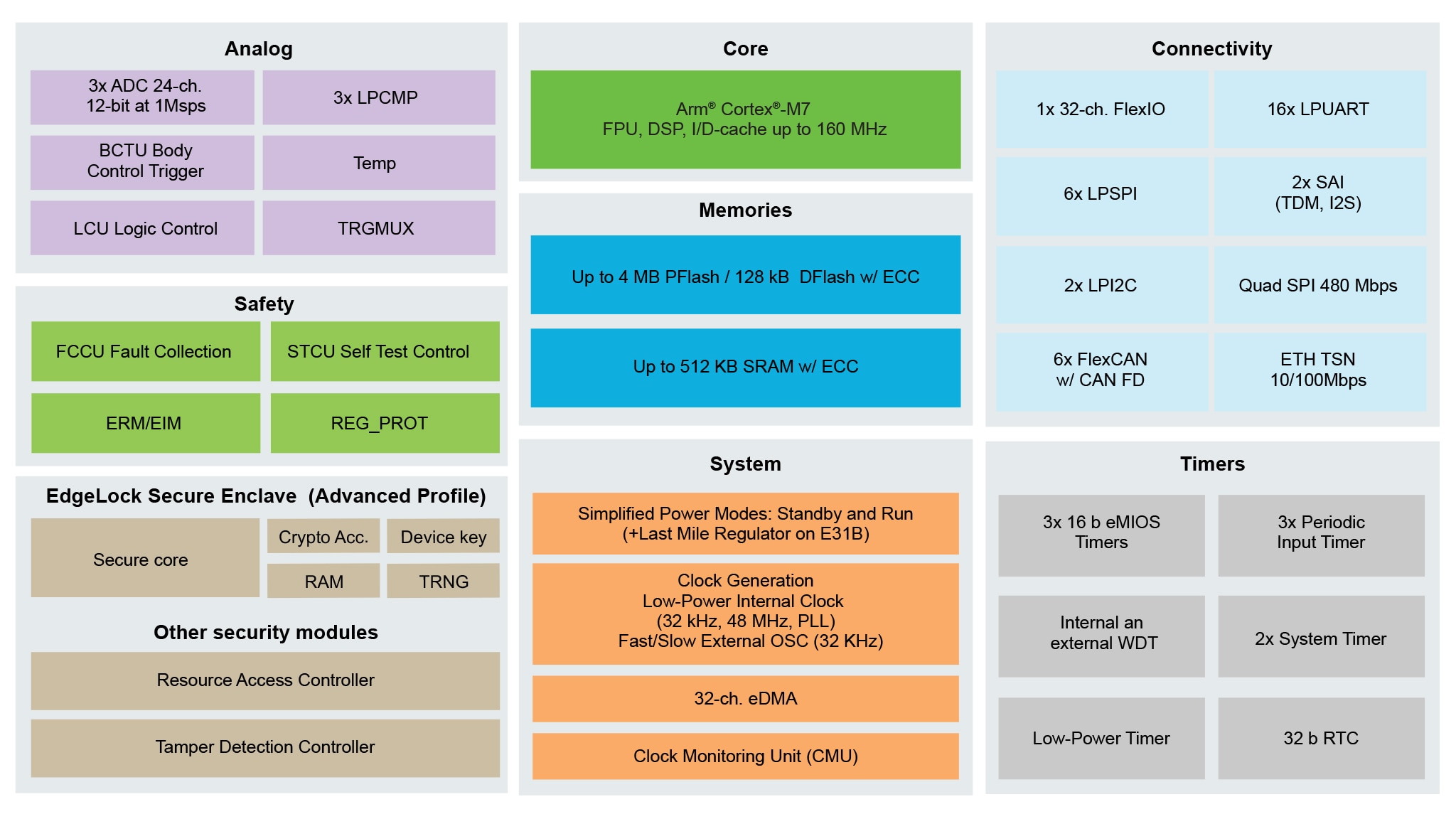

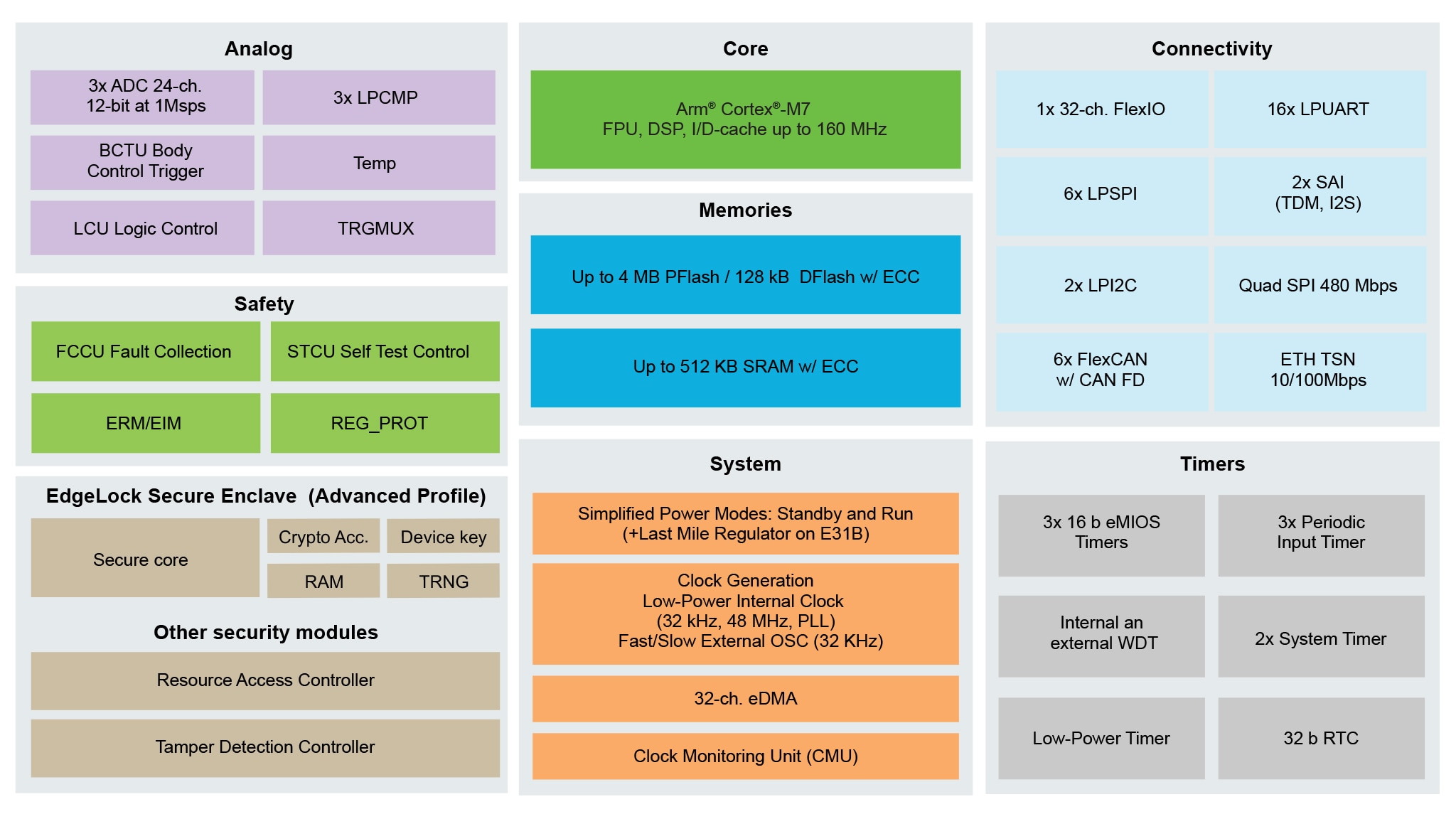

MCX E31 Series Block Diagram.

MCX E31 Series Block Diagram.

For a better experience, download the

block diagram.

The MCX E31 family provides a hardware-level solution. With on-going SIL 2 hardware integrity certification by TÜV SÜD* a systematic path toward SIL 3, and integrated EdgeLock Secure Enclave, MCX E31 reduces the burden of safety and security compliance. Coupled with an industrial qualification up to 135 °C and a 10-year lifetime profile, this translates into consistent operation that minimizes downtime and unexpected field failures.

Key Features at a Glance:

- 160 MHz Arm® Cortex®-M7 core with FPU/DSP

- Up to 4 MB Flash and 512 KB SRAM with ECC protection

- EdgeLock Secure Enclave with PSA Level 2 certification

- Integrated Power Conversion & Motor Control (PCMC) subsystem

- Up to 6x CAN FD and 10/100 Mbps Ethernet with TSN

- High-density QFP option doubles I/O in the same footprint for expanded connectivity

- -40 °C to 135 °C extended industrial range with 10-year mission profile

- FRDM-MCXE31B development board support with MCUXpresso SDK and Application Code Hub

What This Solves for You

Modern embedded systems face mounting pressure to deliver not only high performance, but also proven safety, long-term reliability and streamlined design. The MCX E31 family addresses these challenges head-on, offering hardware-level innovations that simplify certification, strengthen system resilience and reduce the need for multiple MCUs. Here's how the MCX E31 portfolio helps solve the most persistent pain points in industrial and appliance development.

Ready for Safety Certification

Instead of relying only on certified libraries, MCX E31 integrates safety into the silicon. Program flow monitoring, redundant watchdogs and error reporting build a hardware-level safety baseline that accelerates certification and reduces the cost of demonstrating IEC 61508 compliance for a system.

Rugged and Reliable for the Long Haul

One aspect of reliability is temperature tolerance, but that’s not the whole story. Engineers also need mechanisms that safeguard against data corruption and unpredictable faults. That’s why MCX E31 includes error correction code (ECC) on Flash and static random-access memory (SRAM), clock and supply monitoring and fault collection with programmable system response. Regardless of stress, data integrity and predictable system behavior enable equipment to can operate safely without unscheduled downtime.

More Functionality, Fewer MCUs

Compared to the MCX E24’s Arm Cortex-M4F core, MCX E31 boosts performance for compute-intensive applications with a 160 MHz Arm Cortex-M7 core. MCX E31 goes even further by directly integrating a dedicated motor control and power conversion subsystem, Ethernet time-sensitive network (TSN) and up to six controller area network flexible data-rate (CAN FD) interfaces. By combining high-performance compute, mixed-signal control and robust networking, MCX E31 unlocks consolidated system architectures that would otherwise require multiple devices to achieve.

Where MCX E31 Shines: Real-World Impact

The MCX E31 family isn’t just another MCU—it’s the engine powering the next generation of safer, smarter and more connected industrial systems. Here’s where MCX E31 can help developers push boundaries:

Industrial Automation and Robotics:

From high-speed conveyor diverters to precision robotics and drones, MCX E31’s 160 MHz Cortex-M7 core and integrated motor control subsystem enable complex motion, real-time safety and advanced networking, all on a single chip. With support for six CAN FD buses and Ethernet TSN, you can orchestrate a factory floor with maximum reliability and minimal downtime.

Smart Energy and Power Conversion:

Whether you’re developing home or industrial energy storage or distributed battery systems, the MCX E31’s built-in power conversion accelerators and rugged safety features help your designs thrive in harsh conditions, deliver more uptime, and achieve safety certifications faster.

Safe Appliances and Tools:

Imagine HVAC, heat pumps, boilers and power tools that are built to last. With extended temperature range and SIL 2 hardware integrity, MCX E31 delivers years of reliable, secure operation, even in the toughest environments.

Medical, Transportation and Beyond:

From medical pumps and ventilators to public transit controls, MCX E31 is engineered to meet internationally recognized safety standards (IEC60601, EN50128 and IEC61511). So you’re not just building devices, you’re building trust, safety and peace of mind.

Built-in Differentiation

Most competing MCUs approach functional safety by layering certified software libraries on top of general-purpose silicon. This approach is lacking because it adds to the system's complexity and places more of the certification burden on the design team.

MCX E31 is different. Safety is part of the hardware design itself, with TÜV-certified SIL 2 integrity and systematic capability for SIL 3. With it, engineers gain a stronger foundation for compliance, reducing the need for external safety mechanisms.

To further support safety-critical applications, MCX E31 includes a comprehensive safety enablement suite. This includes:

- Memory Test Libraries to supplement ECC coverage and enable real-time memory diagnostics.

- CPU Built-In Self-Test (BIST) capabilities to ensure continuous processor integrity.

- Safety Documentation and Analysis Reports to streamline integration and certification efforts.

Other solutions also depend on less commonly adopted processor architectures that limiting ecosystem support and long-term scalability. MCX E31, by contrast, is built on the widely supported Arm Cortex-M7, removing barriers to entry. As a result, MCX E31 is easier to integrate, better supported by toolchains and more adaptable for future designs.

Developer-Ready Enablement

To move engineers from concept to deployment more quickly, the MCX E31 family is backed by the FRDM-MCXE31B development board. This solution offers immediate access to the device’s peripherals and subsystems in a modular, easy-to-use platform. Features include:

- Arm Cortex-M7 core running up to 160 MHz

- Onboard 10/100 Mbps Ethernet with TSN support, plus up to three CAN FD physical layer (PHY) and connectors

- Arduino, MikroBUS and PMOD connectors for attaching shields and peripheral boards

- Integrated accelerometer, magnetic switch and 8 MB external SPI Flash

- USB Type-C supply with selectable 3.3 V or 5 V operation, plus serial wire debug/microcontroller unit-link (SWD/MCU-Link)

Paired with the MCUXpresso Software and Tools, this solution provides optimized drivers, middleware and on-going certified libraries* simplify bring-up and shorten development cycles. And when it’s time to move faster, the supplementary Application Code Hub (ACH) gives access to more than 140 ready-to-use examples and tutorials, including safety and connectivity use cases tailored to the MCX E31.

FRDM-MCXE31B development board.

FRDM-MCXE31B development board.

Safety-Ready Enablement

Beyond traditional enablement tools, MCX E31 accelerates safety application development through:

- A Base Enablement package with essential libraries and documentation to jump-start custom safety applications.

- The FuSa Development Package (unique in the industry), includes an on-going TÜV-certified Safety Software Framework (SAF)*, which implements fundamental safety functions for silicon operation. Licensed by NXP, this package helps customers save significant time, cost, and engineering effort.

- Integration into NXP’s Safe Assure program, which connects developers to a broader safety community and direct NXP support, strengthening cross-portfolio functional safety engagement.

The MCX E31 Advantage

To recap, the MCX E31 family delivers a unique combination of:

- Built-in functional safety with on-going TÜV-certification* for SIL 2 hardware integrity and systematic SIL 3 capability, with safety development packages

- Extended reliability with qualification up to 135 °C and a 10-year mission profile at 105 °C

- High-performance compute with a 160 MHz Arm Cortex-M7 core and integrated motor control subsystem

- Rich connectivity, including up to six CAN FD interfaces and 10/100 Mbps Ethernet with TSN

- Secure operation through the EdgeLock Secure Enclave with PSA Level 2 certification

Whether you’re designing industrial automation, energy systems or advanced appliances, the MCX E31 family helps you accelerate certification, simplify system design and maximize long-term performance.

Want to learn more about MCX E31 and explore the tools to build with confidence? Check out these resources.

*Targeted certification completion by January 2026.