Formula Student Electric is an international engineering competition where university teams design, build and race fully electric formula-style cars. The program is part of the broader Formula Student (also known as Formula SAE) series, and has become one of the most prestigious global student engineering competitions.

Raftar Formula Racing Electric represents the Indian Institute of Technology, establishing a reputation as one of India’s most decorated student engineering teams. This blog features how collaboration with NXP is equipping students in their journey to design an autonomous electric race car that performs at groundbreaking speed.

As part of our journey in Formula Student Electric, one of the most critical challenges we faced was developing a reliable battery management system (BMS) for a high-voltage pack. The BMS is the brain of the battery. It safeguards the pack, ensures performance, and enables smooth integration with the rest of the vehicle.

For a student team building everything from scratch, this was a daunting but exciting task.

Know the Bright Minds Behind

Starting Point

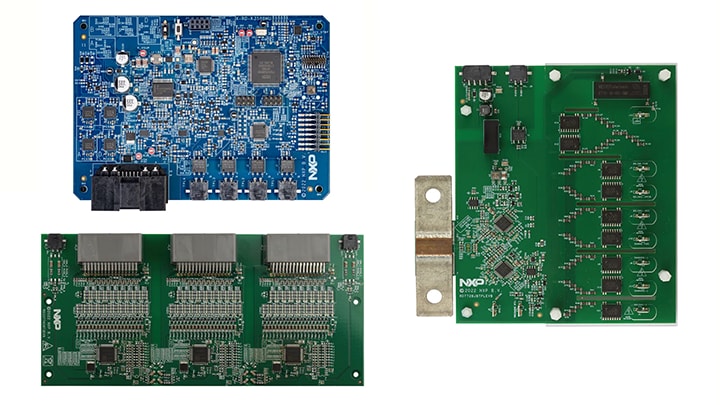

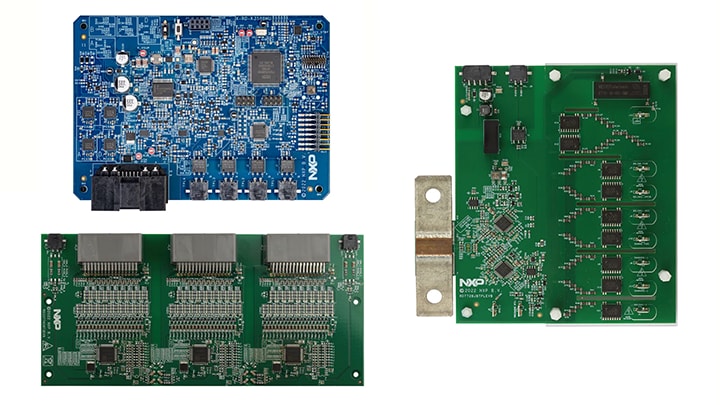

In the early stages, we worked in parallel on the mechanical design of the battery pack and the electrical side, which included the BMS and a companion PCB for critical pack functions. To boost our learning curve, we began by testing out the NXP’s 800 V BMS Reference Design using the ETPL (electrical transport protocol link) Bundle. It includes a battery emulator, a peripheral test board utilizing the MC33774, an 18-channel battery cell controller IC, an 800 V battery junction box (BJB), and the RD-K358BMU battery management unit (BMU), which serves as the main controller.

The NXP HVBMS Reference Design Bundle provides everything needed for developing, testing and demonstrating advanced high-voltage battery management systems.

The NXP HVBMS Reference Design Bundle provides everything needed for developing, testing and demonstrating advanced high-voltage battery management systems.

This setup allowed us to test our initial logic using S32 Design Studio (S32DS). Once we grew comfortable with the drivers and the configuration tools available, we changed to the Model-Based Design Toolbox (MBDT) for further code development.

Moving to Model-Based Design

Although coding through Simulink® was new to us, NXP’s support ecosystem made the shift much easier. We started with the example projects provided by NXP. Which demonstrated basic BMS functionalities, such as reading voltages and analog inputs from the MC33774 through ETPL communication and sending CAN messages to the rest of the car for integration.

From there, we gradually built more complex features over the course of three months of active development, with guidance from NXP MBDT team engineers, leveraging the MBDT community . Through this process, we gained the confidence to expand our software capabilities. The NXP Community forums also played a huge role in resolving issues and sharing insights.

Integration Made Simple

One of the biggest advantages of MBDT for S32K3 was how easy and seamless it was to integrate with the rest of the car. We can directly drag and drop already developed and existing models onto the BMS to add functionalities. For example, the State-of-Charge (SOC) estimation block from our battery model just had to be copied and pasted into the BMS software.

Where We Are Today

Thanks to the power of MBDT and NXP’s support, we’ve developed a robust BMS software stack that includes:

- Per-cell voltage and temperature monitoring

- State of Charge (SOC) and State of Health (SOH) calculation

- Cell balancing algorithms

- Robust CAN communication for integration with the rest of the vehicle

- Comprehensive Fault Detection: Over 200 automated checks continuously monitor the battery for faults, significantly improving safety and reliability

- Smart Contactor Control: The BMS automatically detects charging and discharging states and manages contactors seamlessly, reducing human error and ensuring smooth operation

BMS and S32K3 MBD

BMS and S32K3 MBD

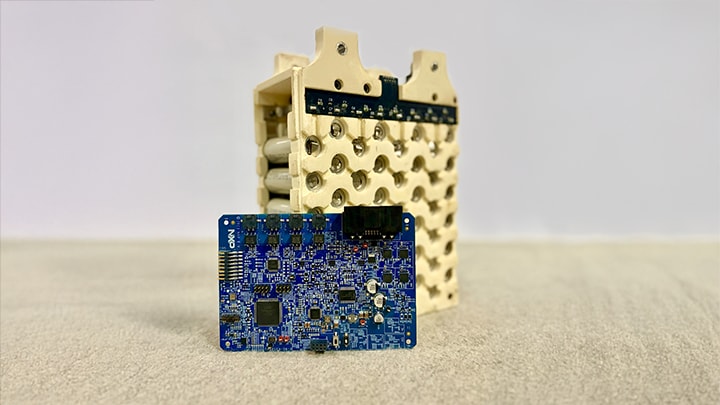

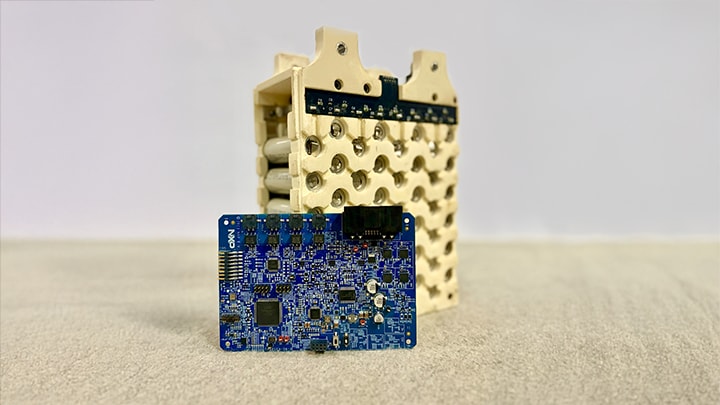

This milestone marks a huge step forward for our team, making it possible for us to run our pack safely and effectively while laying a strong foundation for future improvements such as ML-based thermal run away detection, active cooling algorithms, advanced fault prediction algorithms and other next-generation features. We are also working on developing custom hardware solutions for both the controller and peripheral boards to increase flexibility.

The journey from complete beginners to building a fully functional BMS was made possible by the tools, support and community provided by NXP. The Model-Based Design Toolbox not only accelerated development but also taught us valuable lessons in embedded software design.

We’re excited to carry this momentum forward as we continue innovating in the Formula Student competition.