In my

August post

‘A look at die-level heat transfer’, I introduced the idea of a

MOSFET ‘detailed model’ which could be used for predicting

temperature rise and heat flow in the die at very short times scales. This was

followed by my

September post

‘Top Clip’ where I took the idea of a detailed die model

further, showing how a top clip could be added to a standard D2PAK device in

order to improve the thermal performance of the device over a specific time

range. This D2PAK case was a purely hypothetical example. So in this post I

would like to look at some real devices that use a package which

does have a top clip, NXP’s

LFPAK56 and see how the thermal performance would be affected if the top clip was

not present.

Before I come to that, I’d first like to introduce the concept of

‘transient thermal impedance’. Transient thermal impedance

graphs, also known as ‘Zth curves’ (zed-theta

curves), are a convenient way of describing time-dependent thermal behaviour

without referring to specific power levels or temperature rises. If

you’re not already familiar with Zth curves then I urge you

to take a look at our

Application note – Using Power MOSFET Zth Curves, and in particular the worked example in Section 2.1. I’ll wait a

minute for you to do that… OK, so now we’re all comfortable with

the idea of Zth curves, let’s return to the LFPAK56.

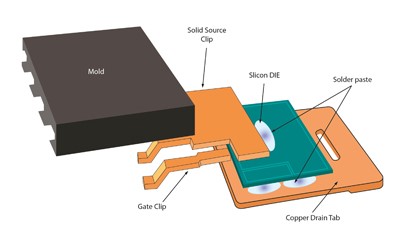

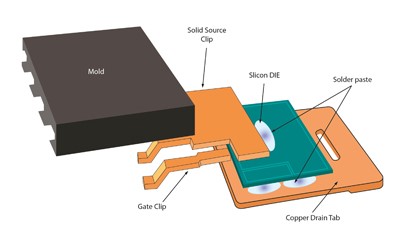

If you look at our focused package page on NXP.com,

LFPAK56 – The toughest power-SO8, in the section ‘Innovative clip-bonding’ you’ll see an

exploded view of the package, which is also shown below. In this case the top

clip is labeled ‘Solid Source Clip’.

Figure 1: An exploded view of an LFPAK56 package.

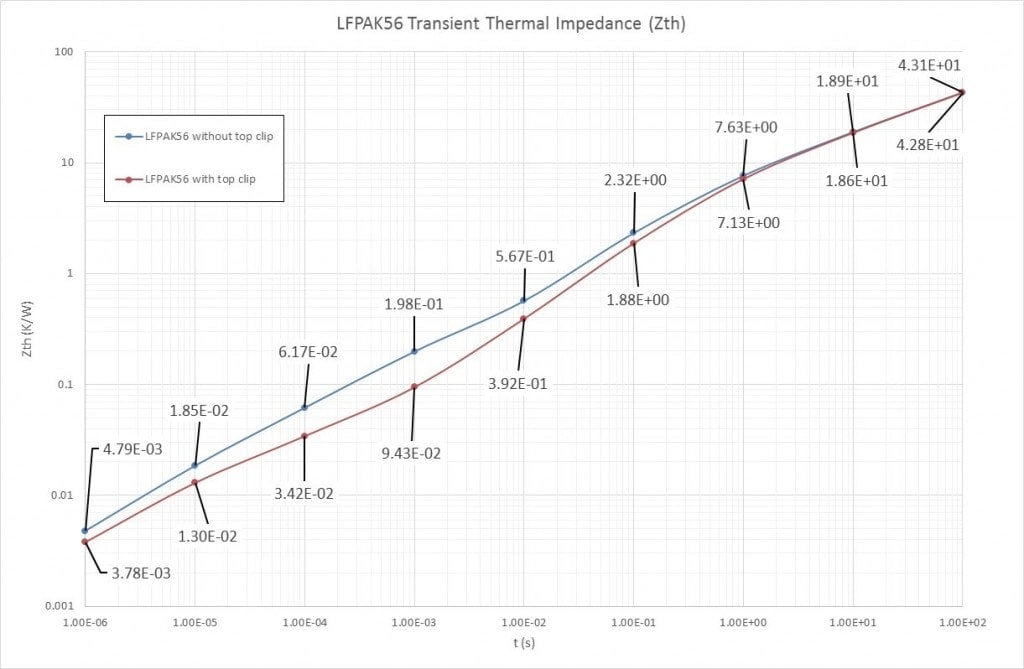

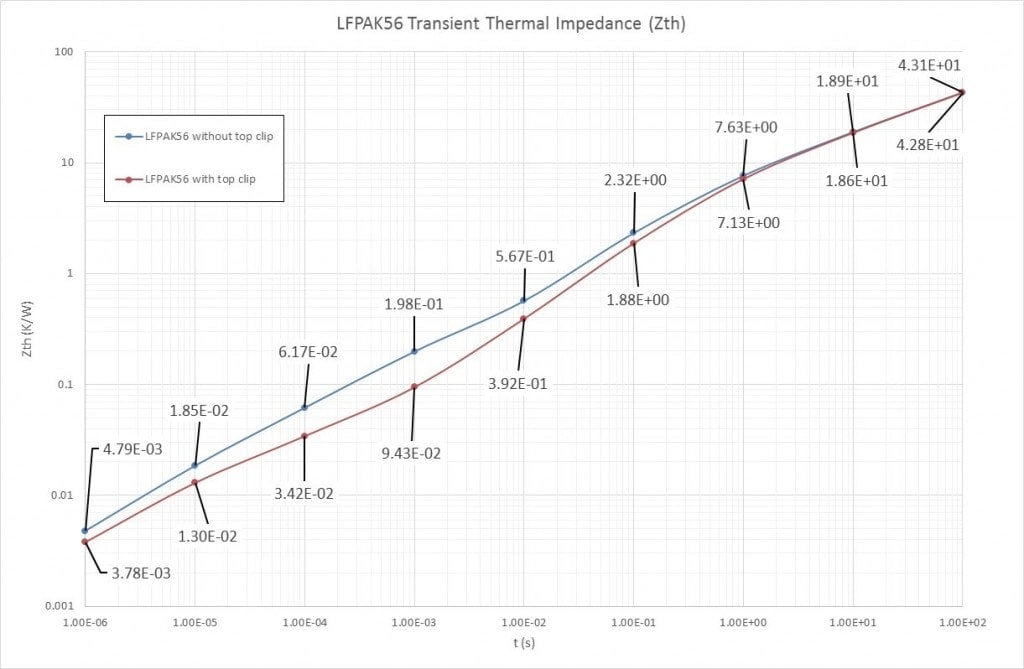

Using the detailed model approach for the die we can produce Zth

curves for an example LFPAK56 device, both with and without the top clip. The

device was modelled on a single-sided FR4 PCB with 1” square of top

copper in the

JEDEC

JESD51-2A test enclosure. The results are shown in Figure 2, and given that

reading numbers from log-log graphs can sometimes be tricky, I’ve

labeled the data points to make things clearer.

Figure 2: Example Zth curve for an LFPAK56 with and without top clip.

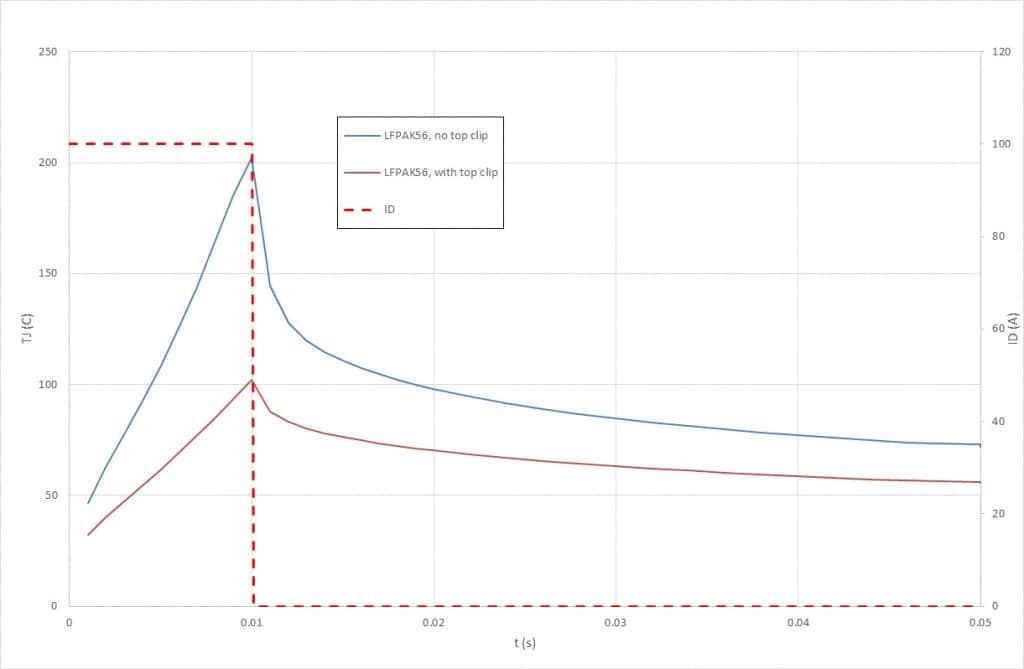

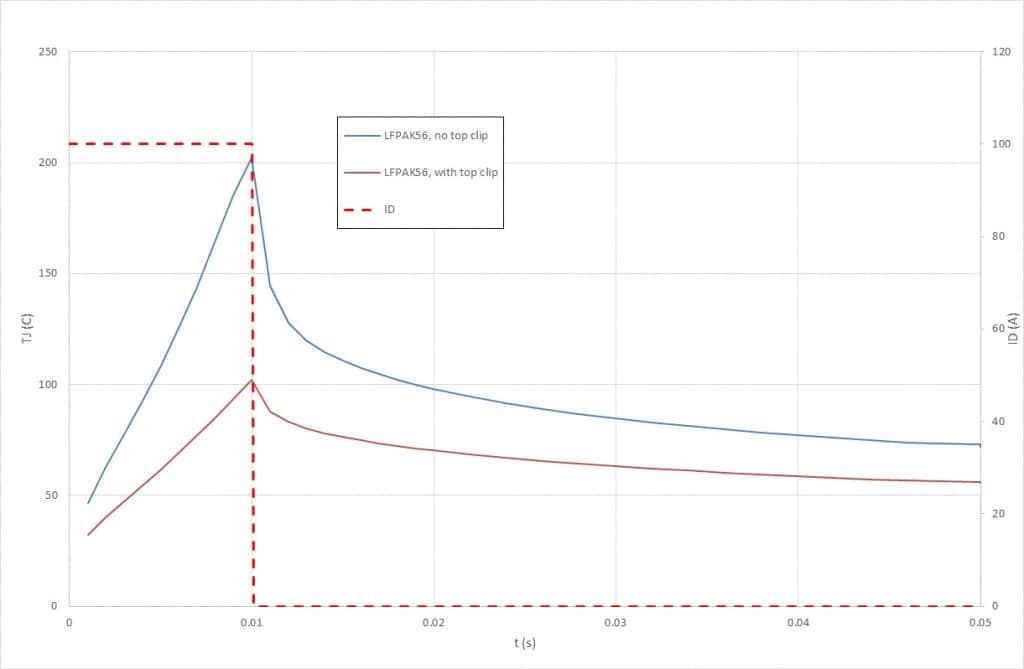

To further illustrate the point I ran two further simulations – again

for the LFPAK56 with and without top clip. This time for the device conducting

a rectangular 100 A, 10 ms current pulse. The results are shown in Figure 3.

Figure 3: TJ for an LFPAK56 with and without top clip when subjected to a

100A, 10ms pulse.

Clearly the top clip is making a big difference. At shorter time scales the

Zth figure is more than halved at 1 ms (Figure 2) and peak

temperature significantly reduced for a 10 ms current pulse (Figure 3).

However looking again at the Zth curves for longer time intervals,

the top clip appears to have less and less effect. In fact once we’re

into the seconds range it has almost no effect at all. This is one of those

‘non-intuitive’ results I mentioned in my

first post: “if I stick a heatsink (i.e. the top clip) on top of something hot then

shouldn’t it always make it cooler?” As is so often the case, the answer to this question is clearly

‘it depends’ – more on this in the near future.

In my next post I will begin an exploration into the interesting and sometimes

controversial topic of ‘top-side cooling’.